The Ford Firestone Safety Nightmare That Ended A Nearly 100 Year Partnership

Founded in 1900, Harvey Firestone's eponymous tire company originally supplied tires for firefighting equipment, wagons, buggies, and other non-powered transportation of the era. Seeing the potential for servicing the budding automobile industry, Firestone soon became a pioneer in the mass production of car tires, a task that was eased considerably by Firestone's friendship with automaker Henry Ford. By 1906, Firestone was supplying tires for all of Ford's vehicles, including the iconic Model T.

Ford Motor Company also enjoyed its share of accomplishments including the utilization of the assembly line and a $5 daily wage for workers — more than double the prevailing rate at the time. But one of Ford's greatest influences on the auto industry didn't come until much later. When the company's Explorer sport utility vehicle debuted in 1990, it was a runaway success that ushered in the modern SUV craze. Available with four doors, it could haul families, cargo, and travel off-road with optional four-wheel drive. All with a sporty appearance.

What nobody knew at the time was that the combination of Ford's revolutionary new SUV and the Firestone tires that it rode on would spark a huge corporate blame game. When the tires failed prematurely and suddenly, the vehicles were apt to roll over, especially in the hands of drivers who had never experienced a tire blowout. In total, over 200 people would perish in accidents involving early Ford Explorers. Based on accident data collected between 1990 and 2001, it was estimated that one in every 2,700 Explorers on the road would eventually overturn, killing someone inside. Both brands would exit the scandal with tarnished reputations and no longer on speaking terms after a 95-year relationship.

The suspension design repeated mistakes of the past

Ford chose to equip its then-latest SUV with a questionable twin I-beam front suspension that was carried over from the smaller Bronco II that it replaced. Unfortunately, this type of suspension is susceptible to changes in camber — the vertical inward and outward tilt of the tire when viewed from the front of the vehicle — as the suspension traveled up and down. It was actually remarkably similar to the design that had caused so much trouble and bad publicity for Chevy's Corvair 25 years earlier.

When the Explorer — which was much bulkier than the Bronco II — proved to be prone to rollovers during tests involving hard cornering, engineers recommended redesigning the suspension or perhaps mounting the engine lower in the frame, but instead, a compromise was reached to run a lower-than-usual air pressure in the front tires. Once again, like the Corvair.

Although the stability of the tall, heavy SUV was actually improved, it came at the expense of greater front tire wear from running lower pressures. Firestone would later claim that the production model Explorers' Gross Vehicle Weight Rating (GVWR) was greater than what was originally represented to the tire manufacturer during the design phase, contributing to the issue.

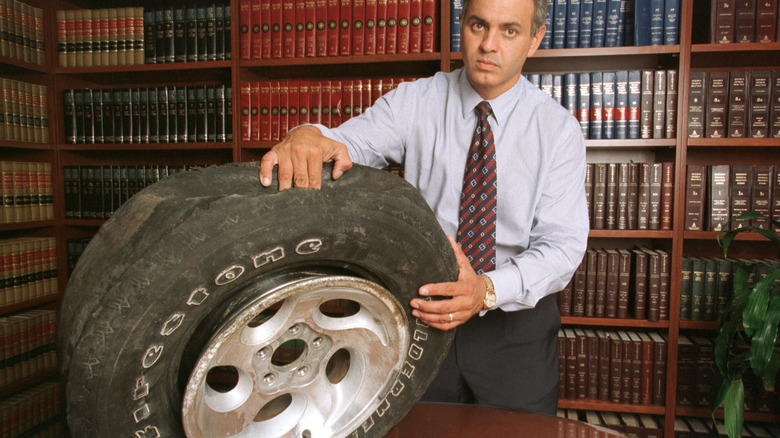

[Featured image by TRC Ohio, NHTSA via Wikimedia Commons | Cropped and scaled | Public domain]

Firestone was also at fault

Over the course of the 1990s, the U.S. National Highway Traffic Safety Administration started to notice the high occurrence of serious accidents and fatalities involving tire failures on the Ford Explorer and its near-twin, the upscale Mercury Mountaineer. Immediately, the production quality of the Explorer's Firestone ATX, ATX II, and Wilderness AT tires was called into question.

Accusations toward the tire maker included a faulty shoulder design which reportedly led to cracking and belt detachment, as well as a different belt adhesion process for tires built in Firestone's Decatur, Illinois, plant compared to other manufacturing locations.

ABC News got its hands on internal investigation details about the issue more than 20 years ago, reporting, "The Decatur plant uses a process known as pelletizing, where rubber pellets are blended with a lubricant to create the rubber that coats the steel belts of the tire. Other plants use a slab system that does not involve pellets." Sadly, it was later confirmed that the lubricant could indeed cause a chemical breakdown, resulting in tread separation.

The scandal prompted passive tire monitoring

In total, 6.5 million Firestone tires were recalled. To err on the side of caution, Ford later recalled an additional 13 million tires at its own expense which were not part of the original recall. Firestone was said to be changing its manufacturing processes at the Decatur plant, where most of the faulty tires were produced, to match its other plants. Instead, the factory was shuttered altogether in the early 2000s, resulting in layoffs for approximately 1,800 employees.

As for Ford's role, the automaker alerted all Explorer owners that the front tires should now be inflated to a pressure of 30 psi, up from the original 26 psi, and checked frequently, especially before long trips. Updated stickers were also mailed to owners to replace the original tire inflation specification stickers in the SUV's doorjambs. For the 2002 redesign, the Explorer featured a completely reconfigured independent front suspension.

In 2001, Firestone CEO John Lampe presented a letter ending his company's 95-year-old business ties to Ford, built on a long-ago friendship. The whole ordeal prompted Congress to pass an overhaul of U.S. tire safety regulations, including the implementation of tire pressure monitoring systems and warning lights that we have today.