Polestar 1 Shows Carbon Fiber Makes Perfect Sense For Hybrids

It's hard to imagine a modern sports car without carbon fiber showing up somewhere, but for Polestar it's Volvo's first outing with the lightweight material. The automaker – which aims to give hybrid and all-electric cars the sort of halo once reserved for high-displacement gas engines in performance vehicles – has been talking up the tech that goes into cars like the upcoming Polestar 1, a model being pulled by forces quite literally from all directions.

As Polestar's halo car – indeed, as its very first car before the company looks to other electric vehicles in later years – the Polestar 1 can't afford to be seen as lacking in technology or engineering compared to grand touring rivals. At the same time, like all electrified vehicles relying on battery power, one significant limit is weight. Push for more electric range and you need bigger batteries overall.

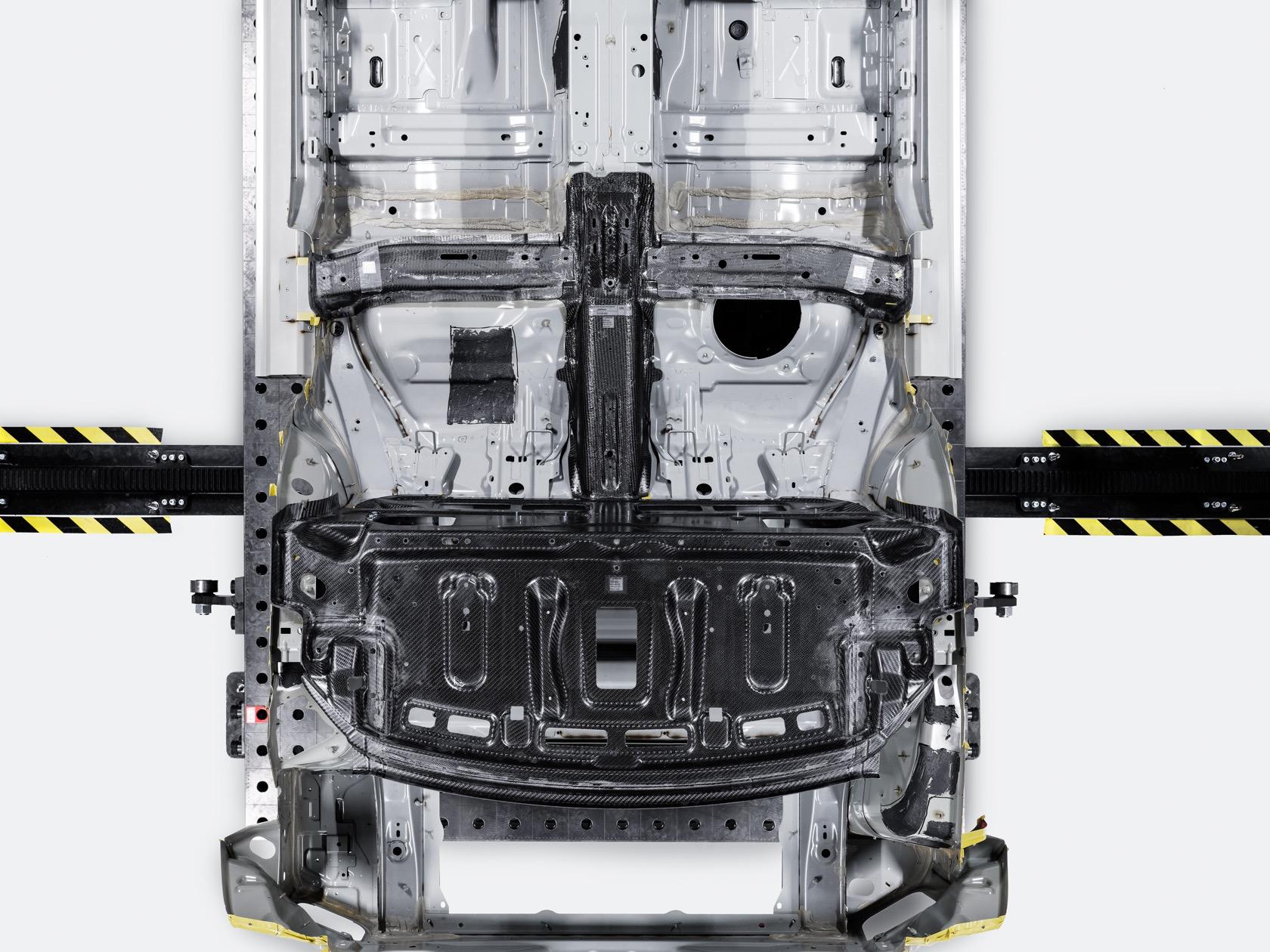

Weight, of course, is the kiss of death for a performance car. The Polestar engineers turned, therefore to Carbon Fiber Reinforced Polymer (CFRP), using it for most of the main body panels – including the hood, trunk, side panels, doors, and the whole roof – and in doing so saved more than 500 pounds versus doing those components in steel.

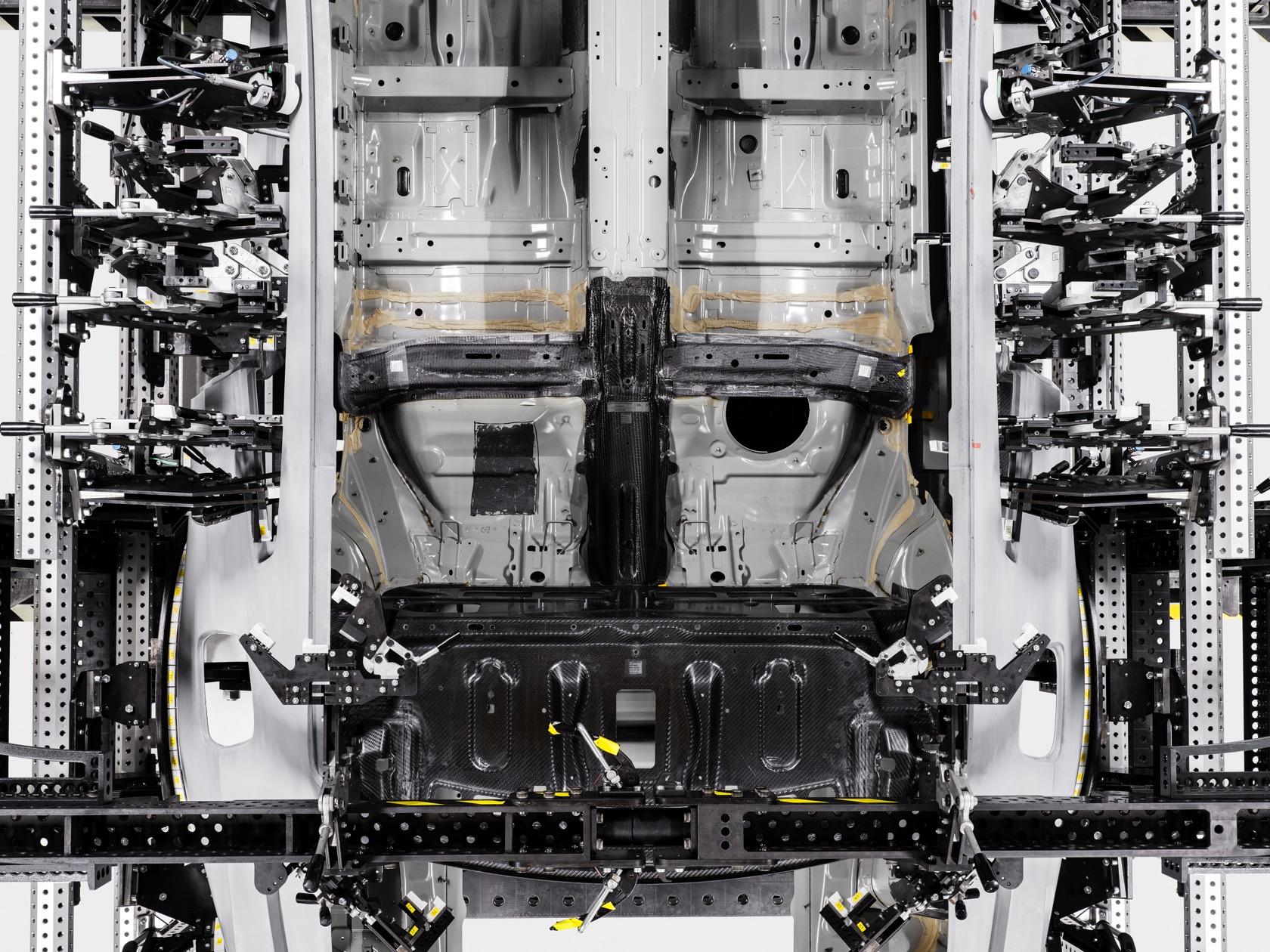

Arguably the most important CFRP part, though, can't be seen, only felt on the road. Polestar describes it as a "structural dragonfly": a section of the material shaped like the insect, and which is bonded to the Polestar 1's chassis. Its "limbs" improve torsional stiffness between the middle floor a rear construction and, the automaker claims, improve it by 45-percent.

Since carbon fiber is lighter than steel, by using the latter for the SPA floor and the former for the upper of the car, the Polestar 1 gets a lower center of gravity. That's both the case technically and visually, too. "Making the whole roof construction out of carbon fibre enabled us to realize that low, elegant roofline," Zef van der Putten, Principle Engineer on Polestar 1, explains.

Indeed, the CFRP allows for crisper feature lines on the hood, more dramatic curves, and flatter surfaces where that's required. It's helped the Polestar 1 concept translate its low and sleek design from show car to what we'll see in dealerships next year.

Of course, there's a gulf of difference between a relatively low-volume sports car and an EV for the mainstream. Polestar only plans to build 500 of its coupe per year, but has much bigger plans for the Polestar 2 sedan and Polestar 3 SUV. Just how much CFRP they'll be able to include in those cars and keep them cost effective remains to be seen.