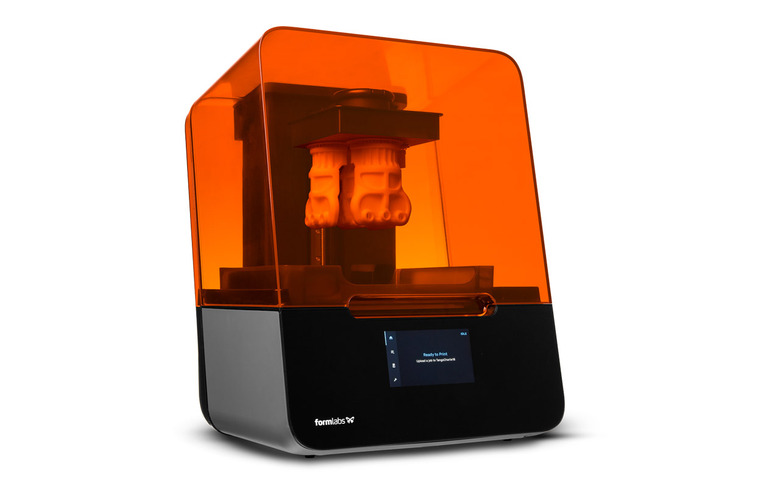

Formlabs Form 3 3D Printer Review

- Setup and operation are extremely simple

- Relatively foolproof cartridge/replacement parts system

- Small format perfect for miniature printing

- Software makes most of the process automatic

- Compatible with a wide variety of resins from Formlabs

- Small format means large prints need multiple parts

- Resin cartridges are not inexpensive

- Printer is priced for professional use

- Formlabs cartridges mean a locked ecosystem

Over the past several weeks we've tested the Formlabs Form 3 3D printer. This printer can be compared to other SLA (stereolithography) 3D printers, but it works with a process that's advanced beyond the models we've reviewed in the past. The Form 3 works with Low Force Stereolithography, a process that allows this printer to create extremely detailed, consistent, smooth prints with minimal support. This printer is extremely easy to use and well worth the cost.

Setup

The Formlabs Form 3 comes in a few parts. The parts are not nearly as difficult to put together as, say, the LONGER LK5 Pro. The bulk of the machine is already constructed and ready to roll in the box.

The only bit that took more than a basic understanding of where to attach what was the balancing of the machine with an included plastic tool. With said tool, the legs of the machine are turned like screws, and the corners of the machine are lifted. The machine's built-in leveling sensor informs the user when they've balanced the machine. The task of balancing this machine took around 5 minutes to perform.

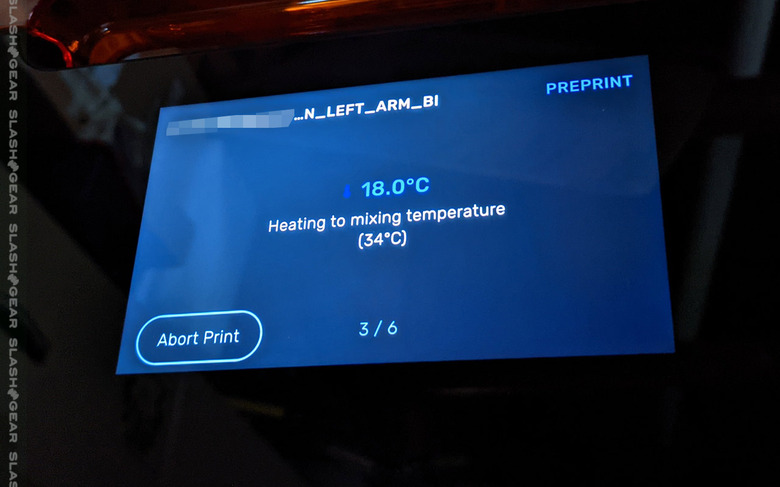

The touchscreen display on the front of the Form 3 is responsive as you might expect a top-notch machine like this to be. The touchscreen display is generally the first place you see a budget machine show where it cuts corners – with the Form 3, you'll find a display that's better than most.

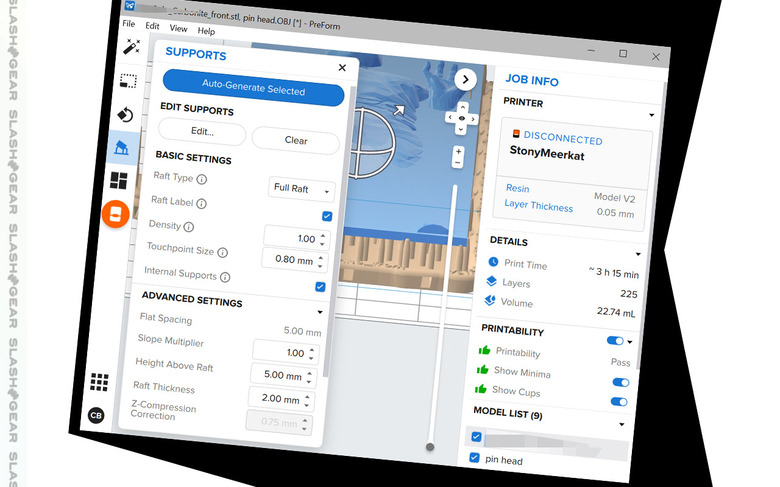

Once the device was connected to WiFi, the process of sending print jobs from a computer to the printer was simple and speedy. Formlabs Form 3 works with an official Formlabs application called PreForm. This app is a miracle worker.

Because of how well paired PreForm is with the Form 3, we had a far, far greater ratio of perfect prints to print attempts than we've had with any other 3D printer we've tested so far. PreForm has different levels of automatic processing – if you just want to set supports automatically, or if you want to drop all your files in at once and have the software do ALL the work for you – it just seems to work, like magic.

Formlabs Form 3 works with a resin system that'll keep you firmly inside the Formlabs ecosystem. You'll buy Formlabs-brand resin cartridges and Formlabs-brand tanks. Much like paper printers of the past, you'll not likely find it worth the effort to attempt to bypass this system with 3rd-party materials.

Formlabs made a cartridge system here that automatically detects the sort of resin that's being used. The tank slots in to the back of the machine, and the resin is allowed to flow down into the tank below. As a tank is first used with a given resin cartridge, it is tagged by the machine. The tank is assigned that resin (via onboard memory) until it is reset by the user.

So if I'm using one resin (with its assigned tank), and I want to switch to another resin, I need only remove the resin cartridge, remove the tank, insert the cartridge I need, insert its matching (assigned) tank, and I'm ready to go. The only bit of cleanup that's needed between one resin and another is in the print platform, and that's as simple as wiping down a flat surface until clear.

Size

The build volume with this printer is 14.5 × 14.5 × 18.5 cm, (5.7 × 5.7 × 7.3 in). It's a compact area for printing. It's still bigger than the Elegoo Mars Pro (at 12 x 6.8 x 15.5 cm), but it's still pretty tiny. You're not going to be printing anything very massive in this machine, unless you're planning on doing so in parts.

If you want a LARGE SLA (MSLA) 3D printer, we recommend you start looking at the Phenom by Peopoly. That printer has a print volume of a whopping 27.6 x 15.5 x 40 cm, and the printer costs less than the Formlabs Form 3 we're reviewing today.

Of course Formlabs also has larger printers, but they'll also cost you a whole lot more than what Peopoly offers. Then again, the whole process with Formlabs printers is in a different galaxy when it comes to a professional software and hardware process – so you'll know where your money went.

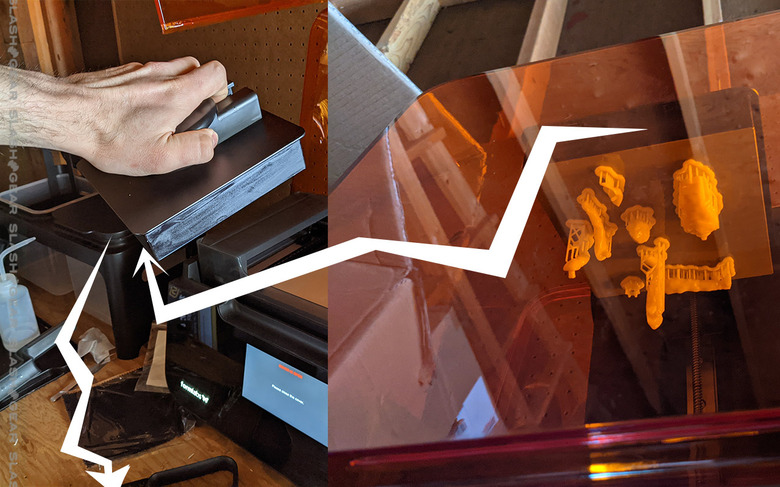

ALSO NOTE: Above you're seeing the print platform as appears in the machine after a print is completed (holding the prints as excess resin drips down). You'll see the print head removed (held by a hand), and the print head as it sits amid the cleaning kit. The cleaning kit consists of two tanks where you'll place completed prints, allowing them to soak in isopropyl alcohol before it's time to dry.

Material Tests

We were sent a variety of cartridges to test with the Formlabs Form 3, including Clear, Model, Rigid 10K, and Color (with a Color Kit). Each material was as simple to use as the other, courtesy of the auto-detecting cartridge system and the software's ability to tell the printer to print according to said material.

With Rigid 10K resin, the final product has a white, matte finish. The resin is glass-filled, allowing it to be extremely rigid and resistant to heat after it's cured. Rigid 10K is the "stiffest material" in the Formlabs print collection for the Form 3. Everything we printed with Rigid 10K felt like it was forged in ancient Greece – it feels like a material that should only be able to be mined from a mountain and carved into statues.

The price of the Rigid 10K is double that of the Clear resin, largely because the makeup of the Rigid 10K is far more complicated than that of the Clear. Clear also isn't nearly so rough and tough as the Rigid 10K – hence the name.

Formlabs Clear resin prints entirely translucent, provided you're working with an entirely clean print platform. As is generally the case with translucent material, any tiny drip of non-clear resin or the smallest speck of dust may be visible in your final product.

It's a testament to the quality of the print process with the Form 3 that we've been able to create such smooth, flawless prints during our review process. The smallest detail can be seen, and the most careful post-print cleaning process must be used. In other words: don't go using rough sandpaper here or you'll get scuffed!

The Formlabs Color Kit is a surprisingly simple package and process for getting exactly the color resin you want to use to print. You can either buy the full kit for $175, or you can get the Color Base Resin for $119 and individual pigments for $19. The Color Base Resin is 0.8L (where most resin cartridges are 1L) because the amount of pigment you put in to the base will result in a total of 1L.

With the Color Kit, we made the color "Coffee". We wanted to make a tone that'd fit the skin tone of action figures we've been using for testing, and Coffee hit the spot. The mixing process was simple, and the result was perfect. We had ZERO mis-prints with the resulting resin.

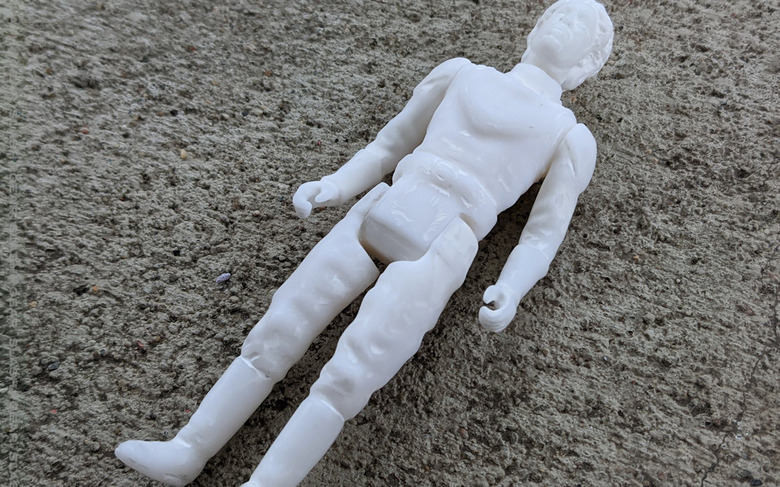

To further test the action figure printing process, we tested Formlabs Model resin. This resin is meant specifically to be a "neutral base tone great for finalizing form and client approval of designs such as character models, figurines, and miniatures."

The difference between what we got with the Color Kit and what works with the Model resin is slight. If we were working with a Form 2, we'd be able to print at 140 microns (faster print, lowest resolution), while both resins work with 100, 50, and 25 micron options for the Form 2, Form 3, and Form 3B. The Model resin also required post-curing while the color did not.

Action Figure 3D printing tests

If I were attempting to make an action figure that was going to be thrown around and played with, I would NOT choose the Rigid 10K. If we're printing this tiny, the rigidity creates a situation where there's a possibility that we're going to have breaking parts. Usually this won't be an issue with what Rigid 10K is meant for. Here, it creates a final product that could be placed on a shelf and admired for many years – but when something does not bend, it can break.

Clear resin would be ideal if I had a reason to need to see all the parts of the model. The only drawback here is if I am printing an articulated action figure, I can see the joints, and the pegs, and so forth. Clear resin is fantastic for one-part prints, like the skull you see above. That skull is tiny, and super, super sharp.

Also note again that it's not very easy with any resin 3D printer like this to get a truly transparent print. Make absolutely sure that ALL of your parts are completely clean and clear before you pour the resin, and don't let anything contaminate your tray!

Model Resin V2 is great for showing detail. You'll see light and shadow with the greatest of ease. This is another resin that's best for prototyping. It's meant to have a little give – unlike what you get with the Rigid 10K. If you're printing with extremely tiny and delicate joints, like we are here, it's very possible for this resin to rip.

The most excellent resin we tested with this printer for this action figure test was the color kit. The color was exactly what we wanted – it matched the guide included with the kit precisely. The print quality is sharp, and the final product's rigidity is just the right point between hard and soft.

With this standard Color Kit resin, parts can bend JUST a little bit for the pieces we've printed, just enough to pop appendages into sockets without ripping or snapping.

Wrap-up

The Formlabs Form 3 3D printer is not the most budget-friendly machine for the everyday average creator. The basic package includes the printer itself, a single resin tank, a Form 3 build platform, and a Form 3 Finish Kit, as well as a 1-year warranty. For that – not including any print materials – you'll be paying $3,499 USD.

For 1 liter of the most basic Grey Resin, you'll pay $149 USD. We've used the Clear Resin (also $149), and Rigid 10K Resin ($299), as well as the Color Kit ($175). You'll need to either clean your resin tank each time you switch resins, or buy a resin tank for each different material. One Form 3 Resin Tank will cost you approximately $149 USD.

You can also purchase a stainless steel build platform for $250, or a standard build platform for $99 USD. That's the bit that your print sticks to as it's being lifted from the resin. If you're the sort of person who likes to print as fast as possible, you may want an extra build platform so you can switch and keep printing while you remove your just-printed parts from your other build platform.

Formlabs created a printer here that's top-level professional, made to create essentially flawless 3D prints in a wide variety of materials with the greatest of ease. This is far and away the most excellent 3D printer we've reviewed on SlashGear so far. If you want the best compact 3D printer money can buy without having to special order industrial-sized machinery, this is it.