Ford Reveals $11.4bn EV Investment In Its EV And Battery Future

Ford is betting big on EVs, revealing plans for Blue Oval City, a new "mega campus" that's part of an $11.4 billion investment in manufacturing for electric vehicles like the F-150 Lightning. The nearly six square mile facility will be part of Ford's largest single investment in new manufacturing in the automaker's history.

It's an extension of the existing collaboration between Ford and SK Innovation, and on top of an extra $250 million investment in three of Ford's southeast Michigan facilities announced earlier this month. $5.6 billion alone will go toward the new campus, located in Stanton, Tennessee.

There, assembly production is expected to begin in calendar year 2025, Ford says. In parallel, Ford and SK are also set to open two battery plants in Kentucky, the first scheduled to open in 2025 and the second the following year. Altogether, there'll be nearly 11,000 new jobs created across all three facilities.

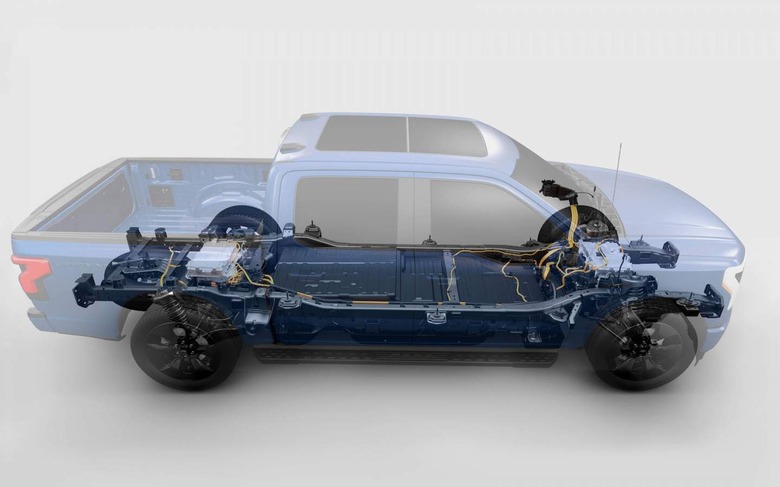

Blue Oval City is being billed by Ford as a perfect example of vertically integrated manufacturing. While it'll be the home of the next generation of electric F-Series trucks, it'll also feature a BlueOvalSK battery plant, along with other key suppliers. Redwood Materials, the battery recycling specialist Ford already inked a deal with, will also have a facility on-site, helping close the loop for EV batteries once they've reached the end of their mobility days.

The facility will be carbon neutral, and zero waste to landfill, once operational. It'll use freshwater only for human consumption; manufacturing will rely on recycled supplies. "We're focusing not just on what we make, but how we make it," Bob Holycross, VP of Sustainability, Environmental and Safety Engineering explains.

The battery facility at Blue Oval City will eventually produce up to 43 gigawatt hours per year. Its counterparts in Glendale, Kentucky, are also earmarked to produce 43 gigawatt hours per year, for a total across all three locations of 129 gigawatt hours. Ford – which says that's sufficient for over one million EVs – plans to use the batteries for future Ford and Lincoln models.

Even then, it may not be enough to sate the automaker's appetites. "We think one third of the full-size pickup segment will be fully electric by 2030," Lisa Drake, Chief Operating Officer at Ford, predicts. In total, 40-percent of Ford's market in the US is expected to be EVs by 2030, or around 1.5 million units. Globally, that split could be as high as 50-percent. This significant uptick in battery production is the first step to satisfying demand from that.

"This was part of our strategy to get to the $80 per kilowatt hour plan," Drake says, "in the back half of the decade."

Clustering facilities together in Blue Oval City is a "significantly larger" vision than before, Drake points out. "If there's one thing the chip crisis showed, it's that we need to have US domestic supply in things as critical as battery materials." Incentives from both Tennessee and Kentucky helped seal the deal when it came to location – particularly in training grants – but Ford is particularly proud of the nature of the jobs, too.

As Drake points out, there are very few battery plants in the US today, so it's an area for potentially very significant growth. $525 million of the investment will go on training new EV technicians.

As for what Blue Oval City will actually produce, there Ford is fairly coy. The facility – around three times the size of Ford's existing Rouge Electric Vehicle Center in Dearborn, Michigan – will be the home for new F-Series EVs, building on the successful reception of the yet-to-launch F-150 Lightning. That needn't just be limited to F-150 variants, either, though Ford isn't talking specific models yet.