Why (And When) Did Cars Switch From Generators To Alternators?

From the earliest days of motoring, cars have evolved dramatically. The very first car envisioned by Carl Benz bears little resemblance to the vehicles we drive today; since then, engineers have found better, safer, and more efficient solutions for nearly every system on the vehicle. For instance, older cars relied on basic mechanical drum brakes, while most modern cars use anti-lock braking systems (ABS), electronic stability control (ESC), and hydraulics as standard.

Another major milestone for the auto industry was the pivot from generators to alternators. So when did this shift occur, and what exactly made it so important? The switch from generators to alternators happened in 1960 when Plymouth came out with the Valiant — one of a few classic Plymouth cars that are totally underappreciated. The main reasons why manufacturers switched had to do with alternators having a higher output, being more reliable, and weighing less.

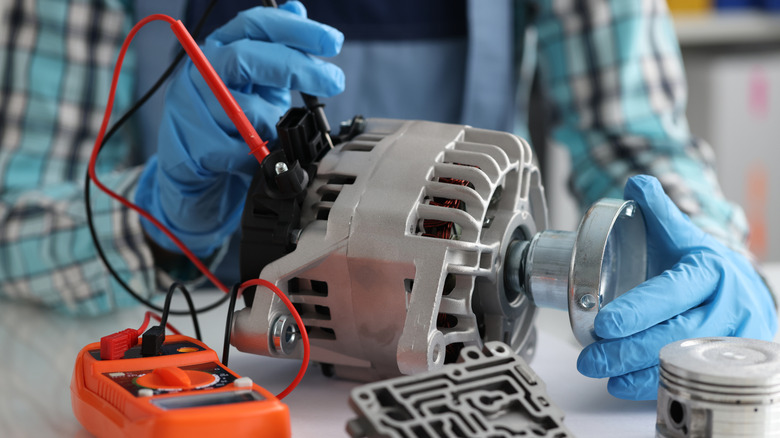

One of the main drawbacks of generators is that they can't produce enough power at lower RPMs while also being trickier to maintain due to how they're built, as they rely on brushes and commutators instead of the alternator's stators and rotors. If we also add the fact that newer cars have a substantially higher energy demand, generators soon became insufficient. By the 1970s, as much as 90% of cars had made the switch, and even today, alternators are the default in virtually all internal combustion vehicles.

Alternators: better than car generators

The 1960s and 1970s saw cars adding a multitude of new electrical features such as stereo sets, halogen headlights, intermitent electric wipers, rear window defoggers, and eventually even on-board electronics and integrated circuits. All of this has substantially increased power demand, and a traditional generator simply couldn't keep up. This is because not only is an alternator able to create a higher output, but it is also a lot more efficient.

For instance, alternators have efficiency rates of 90% to 95% thanks to their smooth slip rings that aren't prone to much movement friction. In comparison, generators suffer higher energy losses, with efficiencies between 75% and 85%. This is mostly thanks to the higher level of friction created by the commutators used in generators. These commutators, and other generator components like brushes, are also expendable parts and require regular maintenance.

Alternators are lighter, easier to mount, and take up less space inside the engine bay. These benefits were formally documented by W.E. Carter in his 1963 SAE technical paper, one of the very first explanations why alternators are better. Car alternators are also long-lasting, capable of providing service for more than 200,000 miles of operation. Generators, on the other hand, require more maintenance and are unable to last as long.

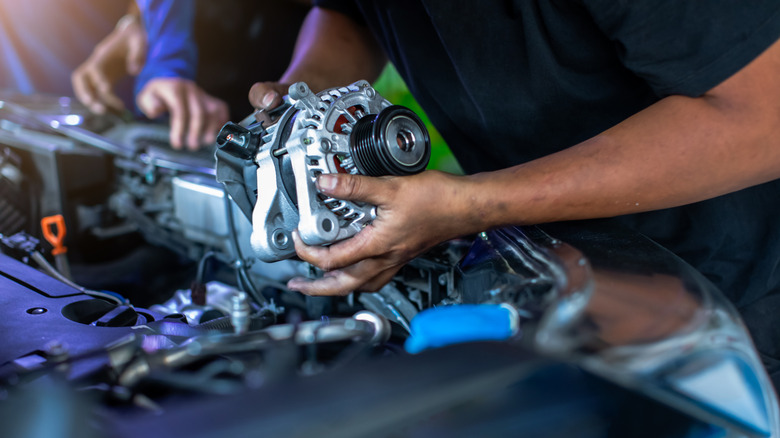

Making a generator to alternator conversion

The popularity of classic cars has seen a resurgence in recent years, but no one can deny that they are just not as advanced as modern vehicles. This is where restomod project cars come in. These classic cars feature modern technology upgrades that improve performance, safety, and reliability. While some classic car enthusiasts might balk at not using original parts in a restoration, there are good reasons to do so; according to Tim Murray on the YouTube channel Classic Motorsports, "if generators were a good idea, we'd all still have them on our cars, and we don't."

As such, some people are interested in converting a generator to an alternator to enjoy all the benefits of modern electrical performance while still preserving their classic car. One of the most difficult parts of making the conversion is the wiring and the mounting, so making sure you have all the necessary diagrams and know what each wire does is essential. The first thing you need to do is choose the right alternator and the output best-suited for your vehicle. When installing the alternator, be sure to use proper mounting and adjust it so it does not rely on a single mounting point.

Often times the old wires will not be able to handle the higher output, so be sure to run a new master charging wire from the alternator to the battery. It's also a good idea to install a fusible link for protection against short circuits. If you are not mechanically minded and don't have the necessary experience, it's best to leave this to a professional, as working on a car's ignition system can be dangerous. Moreover, not all cars use the same diagrams, and works with one car does not necessarily work with the other.