This Material Can Withstand Up To 2,000 Degree Temps - Here's What NASA Made It Out Of

As America's premier space exploration agency, NASA is consistently at the forefront of developing innovative new technologies. This was once again the case when the organization announced the creation of Alloy GRX-810, which can stand up to insanely high temperatures of 2,000 degrees Fahrenheit. This new alloy came from a process that distributed nanoscale oxide particles into a metal base, which was then 3D printed.

It might sound like a DIY method for generating a new alloy. But GRX-810 is stronger and more flexible than anything NASA, whose Dream Chaser will make its debut in 2026, was using at the time. The new metal is also up to 1,000 times more durable than others the agency has created. That's because an Oxide Dispersion Strengthened (ODS) alloy, by its very nature, doesn't fail as quickly as other alloys. This makes GRX-810 perfect for use in not only rocket engines, but also spacecraft as well.

Before NASA actually printed this new alloy, the organization decided to run some simulations first. This would allow scientists to determine the right mix of elements beforehand, thus cutting down on the time and money it would typically take for testing. But it only took 30 simulations for NASA to get the information it needed. Because of this data gathering effort and overall preparation, Alloy GRX-810 far exceeded expectations.

Alloy GRX-810's path to mass adoption

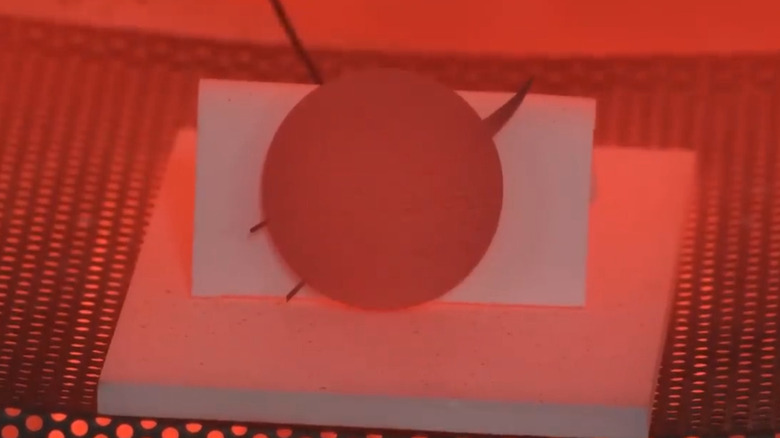

NASA's development of Alloy GRX-810 reached a new milestone in 2023 when 3D Systems, the company that first introduced 3D printing to large-scale manufacturing, performed tests on the new material. This was done via the company's Direct Metal Printing platform, which confirmed GRX-810's strength, malleability, and overall heat resistance. Because of these findings, Alloy GRX-810 was proven to be the advanced solution that NASA had previously stated it was.

NASA, which used a satellite to send the first radar images of Earth's surface, continued with its efforts to bring Alloy GRX-810 to full adoption in 2024. This came in the form of exclusive licenses being granted to four different U.S. companies: Carpenter Technology Corporation, Elementum 3D, Linde Advanced Material Technologies, and Powder Alloy Corporation. This move allowed all four companies to go into full production and distribution of the new alloy.

Since then, Alloy GRX-810 has been used in various components, including liquid jet rocket engine injectors. The alloy has performed as expected so far, holding up reliably under testing conditions. As of 2025, Elementum 3D had begun producing the new alloy on a large scale, distributing it to both the aerospace industry and commercial companies as well. The new metal was so successful that Vectoflow, a European air flow data and systems company, began testing it for its high-temperature flow sensors. In recognition of GRX-810's innovation, NASA awarded the Glenn Research Center its 2024 Commercial Invention of the Year award.