Toyota Sets Target Launch Date For 'World-First' Solid State EV Battery

In October of 2025, Toyota Motor Corporation and Sumitomo Metal Mining Co., Ltd. announced that the two companies have inked a joint development agreement to mass produce the cathode materials that will go into solid-state batteries that will be used in Toyota's electric vehicles (EVs). Toyota plans to launch these EVs with their solid-state batteries into the market in the 2027 to 2028 time frame.

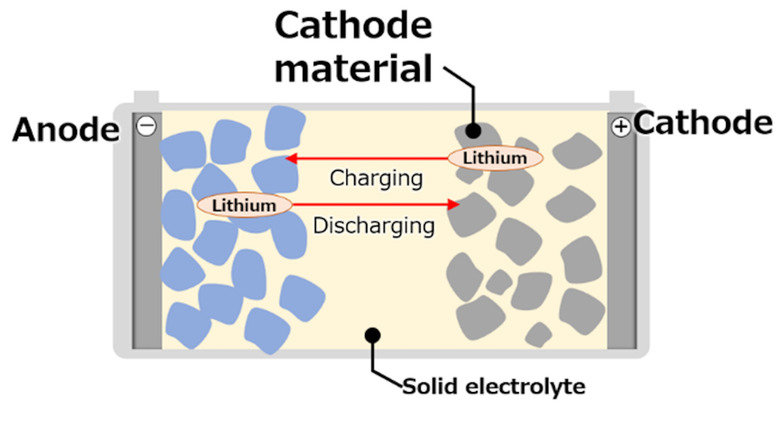

The promise of solid-state batteries and how they work is that the EVs using them will be the next generation of battery technology, going far beyond the capabilities of current liquid-based batteries. Solid-state batteries, made of a cathode, an anode, and a solid electrolyte, have been promoted as offering higher output, longer driving range, quicker charging times, and extended battery life. Solid-state batteries are also touted as being smaller and therefore lighter than liquid-based batteries, with a greatly reduced risk of EV fires, which is a hard battle firefighters face.

Toyota and Sumitomo have been working together on solid-state battery research since 2021 and have overcome the issue of degradation of the cathode material during an EV's many charging and discharging cycles, using Sumitomo's powder synthesis technology. The result is a "highly durable cathode material" for solid-state batteries. Between now and 2027-28, the two companies will be working to reduce the costs of solid-state batteries for mass production by improving the cathode material's safety, quality, and performance.

What else should you know about Toyota's solid-state batteries for EVs?

This joint effort by Toyota and Sumitomo is more than just a technology development. It is an attempt by Japanese manufacturers to get back some of the EV momentum that has been lost to China. China is now the world's leading manufacturer of electric vehicles and has announced its plans to produce semi-solid-state batteries, which use less liquid electrolyte but are not pure solid-state batteries. South Korea has also built up a lead over Japan in the race to produce EVs that are accepted by the world market.

Toyota and the other Japanese manufacturers now realize that the home country must build a supply chain that can provide solid-state batteries for the next generation of EVs, whether they will be produced in Japan or in other Japanese-owned factories around the world. The total amount of Japanese investment in this domestic supply chain, by Toyota and other companies, is $7 billion.

Toyota has also announced an alliance with Idemitsu, a large Japanese oil company. Idemitsu is building a factory capable of producing 1,000 metric tons of lithium sulfide, an essential solid-state battery component, each year. Interestingly, the Idemitsu lithium sulfide plant also plans to manufacture solid-state batteries in 2027. While these developments are promising by themselves, there are still many obstacles to be overcome as manufacturers rush to embrace solid-state batteries for their EVs, including the complexities of making them, expensive production costs, and where the solid-state battery materials will come from.