A Tunnel-Boring Machine Named Mary Is Powering Her Way To Build New HRBT Tunnels

A colossal project to reduce traffic in the underground tunnels connecting the Virginia cities of Norfolk and Hampton just had a big breakthrough — literally. Since 1957, the two cities have been connected by the Hampton Roads Bridge-Tunnel (HRBT), which passes for 3.5 miles under the Hamptons Roads channel in the Chesapeake Bay. As part of busy Interstate 64, the nearly 70-year-old tunnel experiences notorious congestion, carrying over three million vehicles each month. By the 2010s, the locals had enough, and city officials green-lit an over-$3-billion expansion project to create new tunnels under the channel. But the tunneling wasn't going to be done with picks and shovels, it was to be accomplished by an enormous tunnel-boring machine named Mary.

After years of preparation and assembly, Mary finally broke through to the other side of her first tunnel. On September 24th, 2025, the football-field sized machine punched through a wall of rock on Hampton's South Island after over two years of tunneling at a rate of around 50 feet a day. Officials, workers, and locals gathered at the exit point, greeting Mary's 46-foot-high cutting wheel with cheers and celebration. Also present was the U.S. Transportation Secretary, Sean Duffy, who commended the community on its support and determination to get the multibillion dollar project moving.

Indeed, the project is unprecedented in several ways. Besides being Virginia's largest transportation infrastructure project ever, the project's contractor reached out to keep the locals engaged. Project leaders even opened a naming contest to Hamptons Roads middle schoolers. The winning proposal came from Saint Gregory the Great High School, who chose the name "Mary" in honor of Mary Jackson, an African American Virginian who worked as an engineer for NASA. It was a fitting moniker for the powerful tunneling machine, a true modern marvel of engineering.

A titanic feat of engineering named Mary

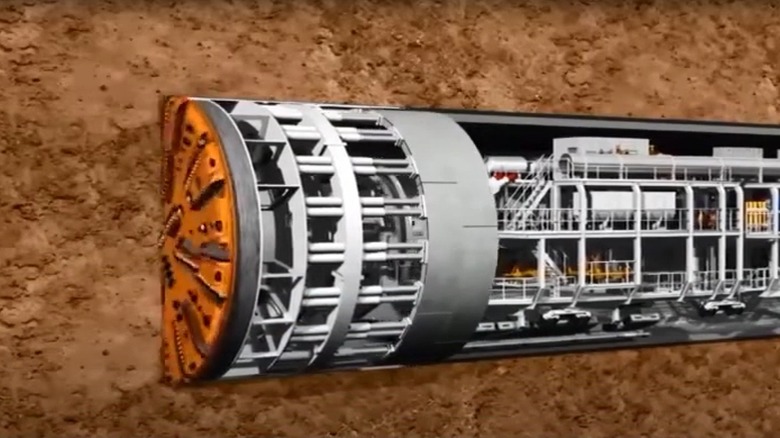

Tunnel-boring machines aren't new. The first can be traced back to 1851, with the Wilson Patent Stone Cutting Machine. And in 1952, James Robbins introduced a modern design that set the stage for today's tunnel-boring machines. The concept was centered around the use of a rotating cutter head flanked by a shielded excavation chamber, where workers can safely remove the excavated materials and reinforce the tunnel walls. Modern tunnel-boring machines follow the same fundamental design but are much grander in scale and scope. For example, one of Elon Musk's companies is the Boring Company, which aspires to create high-speed underground tunnels for electric cars.

But the tunnel-boring machine (TBM) excavating under the Hampton Roads channel is quite a bit wider than the tunneling machines Musk used for his single-lane "Cybertunnels." The German-built TBM has a cutter head measuring 46 feet in diameter, which is about the height of a four-story building, while its total length is greater than that of a football field in order to accommodate the gigantic excavation chamber. Mary's construction, transportation, and assembly alone cost $70 million, and that's not even including the labor and incredible energy costs involved when operating such a fuel-hungry modern machine.

As Mary bores into the rock layer 50 feet below the still-active HRBT tunnel system, workers reinforce the tunnel walls with concrete bracing. The progress has been slow and steady, but there's a light at the end of the tunnel. After years of logistical planning, millions of manhours of work, and billions of dollars, the new tunnel is expected to double the vehicle capacity of the HRBT. For traffic-weary commuters, the reduction in traffic is, ironically, worth the wait.