New Recycling Method Helps Researchers Recover 99% Pure Lithium From Used EV Batteries

The rise of electric vehicles is a critical part of the move away from fossil fuels and the "greening" of transport. However, it isn't without its environmental challenges, one of the major issues being the efficient recycling of batteries. This is especially pertinent when we consider the scale of the problem. Today, lithium-ion batteries power much of the modern world, and it's easy to forget just what a recent innovation this is (interestingly, lithium is formed when a star explodes). Lithium-ion batteries had existed in various formats for decades before Sony introduced the first practical and rechargeable battery in 1991. For the past three decades, the sales of lithium-ion batteries have doubled every two to three years, and with the growth of the EV sector, the growth rate has been close to 40%. That's a lot of batteries to be recycled.

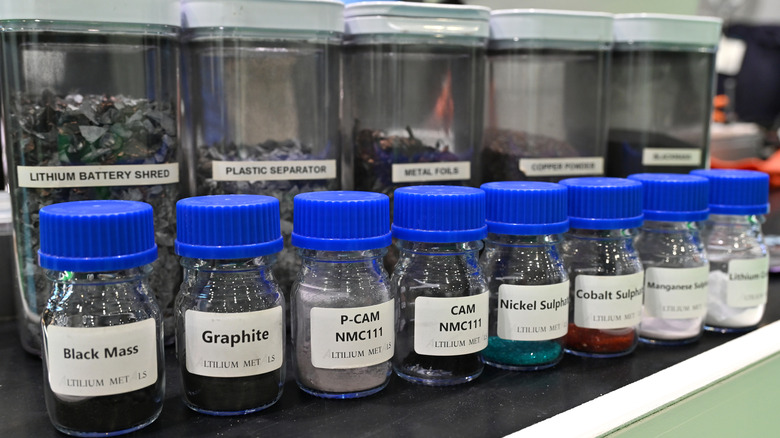

The bad news is that recycling lithium-ion batteries is difficult, hazardous, and expensive. This at least partially explains why, as of 2022, only 5% of the world's lithium-ion batteries were believed to be recycled. Now, one research team has developed a new recycling technology that could improve the situation. The team based at Worcester Polytechnic Institute (WPI) has developed a cleaner hydrometallurgical recycling process that has produced promising results. The process can recover critical metals while producing lithium carbonate at over 99% purity. The research team also demonstrated that recycled lithium, when used in new cathode materials (cathode materials store and release the lithium ions), has a similar performance to new commercial batteries.

A cleaner path to battery recycling

The problems with recycling lithium-ion batteries are multi-fold. One of the most prominent problems is dealing with the materials used in their manufacture. Even after batteries have been disposed of, lithium batteries pose a fire risk. Additionally, many of the materials are highly toxic. Typically, recycling batteries was done using a pyrometallurgy process, which is known to have some fundamental flaws. Namely, the process is energy-intensive, inefficient in terms of materials recovered, and produces significant emissions.

While hydrometallurgical processes aren't without issues (there can be a large amount of chemical waste as a byproduct), it does have distinct advantages. The research team at WPI has shown that their method can recover 92% of critical materials like cobalt, manganese, and nickel from recycled batteries. Once recovered, these can be processed back into effective cathode materials. As noted, one of the major benefits of the process is the pureness of the recovered lithium carbonate, which can be as high as 99.79%, which is above the standards set for new batteries. Battery performance using such materials is also promising; with test batteries retaining 88% of their capacity after 500 charge cycles, and 85% after 900 cycles.

There are also environmental benefits. The process uses 8.6% less energy than other methods and has an overall reduction in carbon footprint of 13.9%. Critically, the method is also highly scalable, which is important given the exponential increase in lithium-ion battery usage. Finally, effective recycling reduces the requirement to source materials like cobalt from countries with histories of human rights issues.