Another SpaceX Test Gone Wrong - Here's Why Metal Tiles Aren't Going To Work

From the outset, SpaceX's tenth Starship test flight in late August looked like a near-perfect success. The massive rocket had a clean launch from Starbase, sailed smoothly into space, and guided itself to a splashdown in the Indian Ocean within a mere few feet of its target. It's the kind of accuracy that would have seemed impossible only a few years ago.

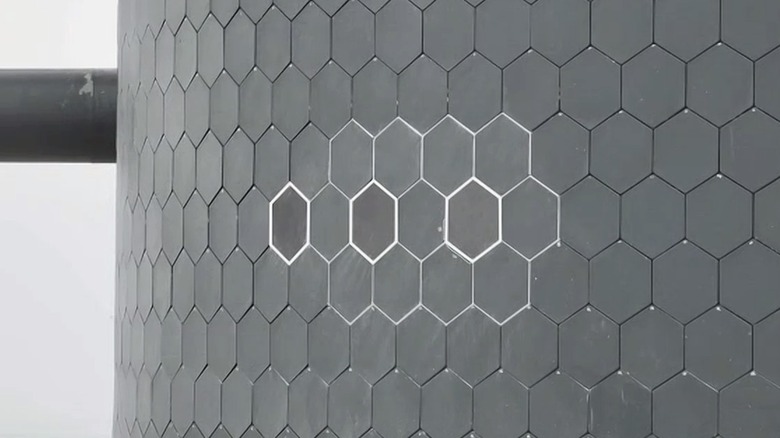

But once the replay videos began circulating, engineers were swift to spot something concerning. The sleek stainless steel sides of the Starship weren't gleaming silver anymore, having been replaced with streaks of a rusty orange hue. Elon Musk later explained that the color came from three experimental metallic tiles that had oxidized during reentry. While SpaceX had hoped for a different result, they noted that some tiles were intentionally removed to test the vehicle's response, and in turn they have now gained valuable data that will help improve the next iteration of the Starship.

Although the mission can still be considered a success, especially when you factor in how many SpaceX rockets have exploded this year, the lesson still hits hard. If Starship is ever going to fly people to orbit, let alone try to go to the Moon or Mars, it needs a heat shield that works every time and can be used again. And right now, that piece of the puzzle is still missing.

What went wrong

Bill Gerstenmaier, a former NASA veteran who is now in charge of build and flight reliability at SpaceX, summed up the result in a straightforward way: "The metal tiles... didn't work so well." Luckily, the problem wasn't a disaster, as the Starship's stainless-steel hull held up. However, the tiles rusted quickly in the high-oxygen, high-temperature environment of reentry. While it may have suffered some serious burns, at least it didn't go up in flames like the previous SpaceX Starship which exploded in June 2025.

The result is not exactly surprising when you consider that NASA played with the same idea in the 1970s, with those tests never making it past the lab. The space shuttle instead relied on 24,000 notoriously fragile ceramic tiles that were the only thing that stood between the orbiter and obliteration. SpaceX is now testing a new "crunch wrap" material to better seal gaps between tiles, having already shown signs of promise on the most recent flight in the form of darker spots against the surrounding burnt white metal.

Metal tiles promised simplicity, but the flight proved they're more complicated than initially believed. They may resist cracks and chips better than ceramic, but if they can't survive the most critical part of the mission, they're a dead end.

The path forward for Starship's heat shield

The patches of white residue where heat seeped through gaps, eroding the protective layer beneath. Engineers have been quick to identify potential remedies to the patches of white residue where heat seeped through gaps, eroding the protective layer beneath. SpaceX now aims to seal the tiles using the new "crunch wrap" approach, which will basically wrap each tile so they interlock more securely, fixing the weak spot without adding the complexity of traditional gap fillers.

That's what Flight 11, expected as soon as October, is meant to prove. If it works, Starship will take another step toward true reusability. Beyond that, SpaceX plans to roll out the upgraded "V3" Starship with improved Raptor engines and refined shielding. Only once that vehicle flies will we know if Musk's dream of a massive stainless steel rocket that can launch, land, and relaunch in quick succession is realistic. SpaceX's ambitions now hinge on perfecting a heat shield that can comfortably handle reentry again and again. Until that problem is solved, Mars and the Moon remain firmly out of reach.