F135 Turbofan: The Incredible Engine Powering The F-35

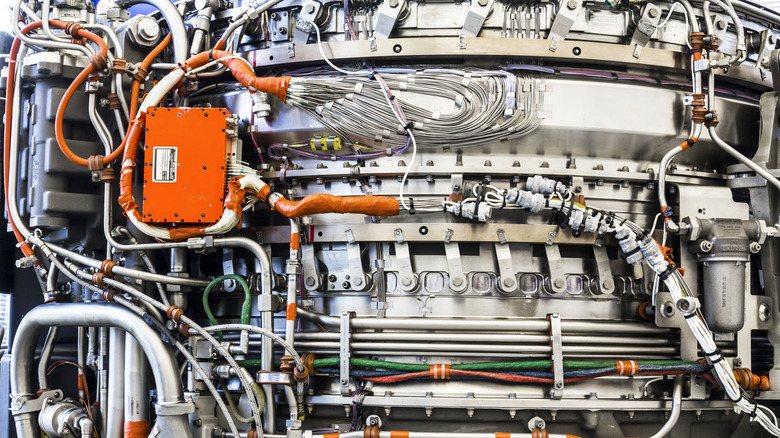

The F135 turbofan engine from Pratt & Whitney powers every variant of the F-35 Lightning II (making it one of the 8 fighter jets with Pratt & Whitney engines powering them) and is the most advanced fighter jet engine in operation. Developed from the F119 that propels the F-22 Raptor, the F135 was tailored specifically for the F-35's demanding mission sets. It delivers over 40,000 pounds of thrust and integrates the world's most advanced engine control system, giving the aircraft exceptional agility and speed. With signature and thermal management and integrated prognostic health monitoring, the F135 is intelligent and adaptable.

This engine supports all three F-35 variants — conventional takeoff (F-35A), short takeoff/vertical landing (F-35B), and carrier-based (F-35C) — allowing for global parts sharing, simplified logistics, and faster maintenance turnarounds. The commonality also enables consistent performance across all platforms, helping allies and the U.S. military standardize and scale operations.

The F135 entered service in 2009 and has now surpassed one million flight hours. Backed by a mature sustainment network across 32 bases and 12 ships, it supports mission readiness from domestic airfields to forward-deployed carriers. As modern threats evolve, the Pentagon confirmed in 2023 that instead of replacing the F135, it would upgrade the engine through Pratt & Whitney's Engine Core Upgrade (ECU) program. This path delivers better thrust and thermal management without the cost or risk of integrating an entirely new powerplant like GE's XA100. Simply put, the F135 is here to stay, and it's only getting better.

A smarter path to the future

The Pentagon's decision to back the F135 Engine Core Upgrade over a new adaptive engine like GE's XA100 (a cutting-edge engine that could power America's 6th generation fighter jets) wasn't just about budget; it was about practicality. The F135 already powers more than 1,100 F-35s in over 20 allied nations (here are more details on which countries fly them and how many they have). Replacing that engine entirely would require significant airframe changes, logistical rewrites, and billions in new investment. In contrast, the ECU is a drop-in upgrade. It preserves existing infrastructure and works across all F-35 variants.

The ECU taps into over a decade of propulsion research, including input from programs like the Adaptive Engine Transition Program (AETP) and Navy Fuel Burn Reduction initiative. It delivers increased thrust, better thermal management, and improved fuel efficiency — all without needing to redesign the aircraft. Pratt & Whitney's plan keeps costs low and reliability high while building a bridge toward 6th-gen propulsion tech.

The upgraded F135 will enable the F-35's full Block 4 capability set, which includes advanced electronic warfare, sensors, and weapons that demand more from the engine. According to Pratt & Whitney, the ECU can be fielded by 2028. Meanwhile, innovations like the Smart Stacking Tool at Tinker Air Force Base, which sped up rotor assembly by 75%, have cut man-hours and improved output precision. In short, the F135 is more than an engine. It's a platform: proven, evolving, and still delivering for the world's most advanced fighter jet.