What Is A Hydrostatic Transmission And Why Isn't It Used In Cars?

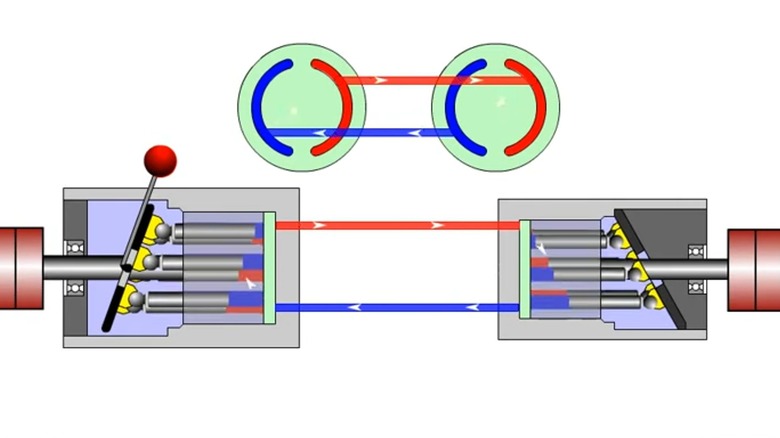

There are many types of different transmission designs which have been developed to offer advantages for certain types of vehicles. A hydrostatic transmission is a unique setup which utilizes hydraulic fluid, has no need for a clutch, and pushes fluid between a pump and motor to create torque. In order to reverse, the hydraulic fluid is forced in the opposite direction, with the pump and motor changing roles. With the ability to vary the force of the pump, there are essentially an infinite number of gears between stopped and full power.

While it can be useful in certain applications, it's not ideal for cars, chiefly because hydrostatic transmissions are ideal for producing immense torque at slow speeds. You'll find these systems in agricultural machinery, such as tractors, construction vehicles like bull dozers, as well as outdoor power equipment like lawn mowers.

In fact, you may be surprised to learn the reason why tractors have such low horsepower, when compared to even small sedans. All of them have to travel at low speed and repeatedly move forward and backward when operating. A car, on the other hand, needs to travel much faster, doesn't require excessive torque at single or double digit speeds, and only reverses in certain circumstances. In addition, hydrostatic transmissions can be quite sizeable,and aren't known for operating quietly, making it a less viable solution for passenger cars.

Most zero-turn mowers use a dual hydrostatic transmission system

With the exception of certain models, like Ryobi's electric riding lawn mowers, fuel powered zero-turn mowers use hydrostatic transmissions. Typically, there are actually two in use on these mowers, with one transmission powering one wheel. This allows either side of the zero-turn mower to operate independently of the other, dramatically enhancing maneuverability.

In fact, the most significant advantage of the zero-turn is its ability to navigate with precision around obstacles with less effort than other options. For example, with a lawn tractor, which features a steering wheel as opposed to levers, you aren't able to make tight turns or switch the direction of travel as quickly.

Because of the increased control offered by a dual hydrostatic transmission system, a zero-turn mower is more efficient, and it can cut areas in less time. Lawn tractors will miss certain parts of the lawn if only driven in one pass, requiring you to pull back around and perform another pass to cut uniformly.

The downsides to a hydrostatic transmission

As well as being ill-suited for high-speed applications and being noisy, there are some other disadvantages to hydrostatic transmissions. Efficiency is severely lacking, with multiple conversions needing to take place during operation. For instance, the pump needs to transform mechanical power into pressure to push hydraulic fluid, then the motor is required to reconvert the fluid pressure back into mechanical force.

During this process, the transmission also experiences loss of pressure, volume, and friction, reducing its overall efficiency. Automakers, by contrast, have sought solutions with more efficiency, with stuff like CVT transmissions, which sometimes get a bad rap.

Hydrostatic transmissions can also be more expensive than other options. For example, a tractor using a hydrostatic system can be a few thousand dollars more costly than a manual or hydraulic transmission option, depending on the model.

The cost difference is, predictably, related to the greater complexity of the hydrostatic transmission. Speaking of, these are closed systems with many parts housed inside of the pump area. This means that any service should be completed by a professional with extensive hydrostatic transmission experience.