When (And Why) Did Cars Stop Using Solid Lifters?

Once upon a time, most car engines used solid or mechanical lifters. But unlike most fairy tales that begin that way, there was no lasting happy ending for them. Hydraulic lifters first appeared in the early 1930s, but solid lifters remained common until the 1950s. It happened with Cadillac's introduction of one of its most ambitious and most iconic engines. This was none other than the V16 engine, which came with the hydraulic lifter.

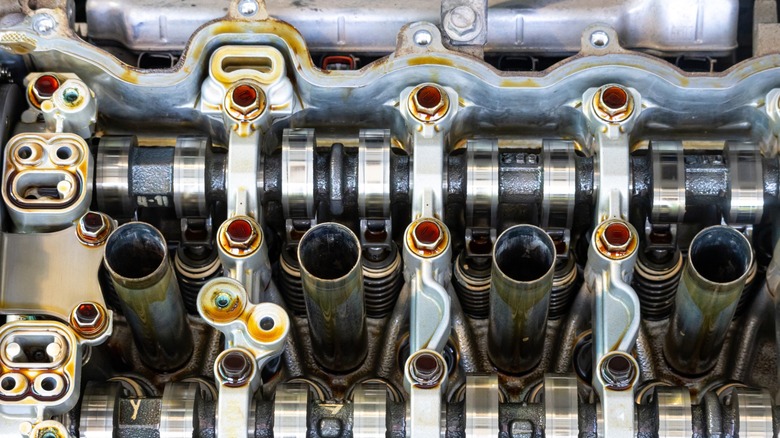

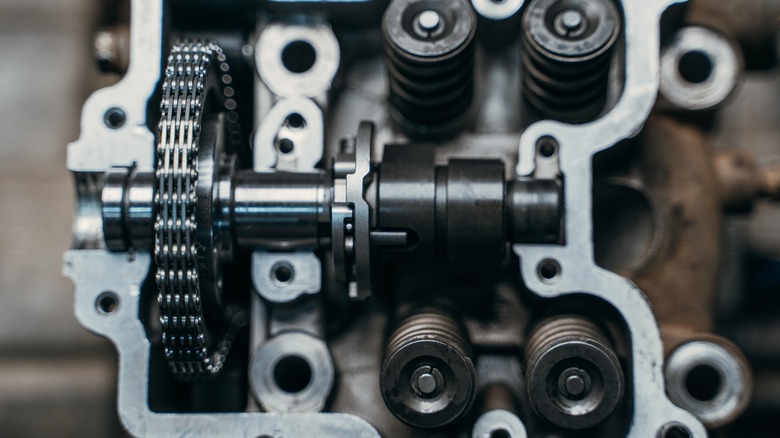

A lifter is a small piece of sturdy metal placed between the camshaft and the cylinder valve. Its job is to transfer the camshaft motion to the valves, thereby controlling the opening and closing of each. This is a very important job as the intake and exhaust valves need to open at different times. So the lifters control which opens and closes when. Each valve also has its own separate lifter.

That Cadillac V16 was the first production car to use hydraulic, self‑adjusting lifters. It introduced the concept of a lifter that auto‑adjusts valve clearance using oil pressure. Cadillac's use of hydraulic lifters in that engine led many other manufacturers to follow suit. And though only a few cars have the V16 engine under the hood, the shift away from solid lifters endured. With that said, here's why cars stopped using solid lifters.

Why car manufacturers moved to hydraulic lifters

The shift to hydraulic lifters was a no-brainer for car manufacturers. The upside became clear to them and the buyers. The shift to hydraulic lifters in mass-produced cars was due to maintenance, noise, and durability. Solid lifters require manual valve lash adjustment every few thousand miles. Hydraulic lifters eliminate that. They don't demand regular adjustment since they are heavier and more sophisticated.

Solid lifters require regular maintenance. This costs time, tools, and can lead to engine damage or noise if neglected. They were particularly noisy during cold starts. They also produced more valve clatter until warmed up. Hydraulic lifters appealed to manufacturers who wanted quieter, smoother engines. Doing away with the need for annual valve lash adjustment was also an irresistible appeal to buyers.

Additionally, hydraulic lifters had improved wear resistance. Without lash adjustments, parts see less stress. Hydraulic lifters adjust dynamically, reducing the valve train wear and extending service intervals. Solid lifters increase wear risk if the valve lash is set incorrectly or drifts over time. Some performance cars retained the solid lifters. This is because they edge out the hydraulic ones when it comes to delivering higher RPMs.