Where Does Sony Build Its PlayStation 5 Consoles?

Sony's PlayStations are the most successful consoles of all time. While the PlayStation 2 takes top billing, the PlayStation 5 can still boast sales of over 77.7 million units since it was released in 2020. This includes later iterations like the PlayStation 5 Slim in 2023 and the Pro, an upgrade with new features released in 2024. But where are all of these consoles coming from? Sony, a company based out of Tokyo, Japan, states that its PlayStation 5 consoles are manufactured at the Kisarazu site in Chiba, Japan, which has been in operation since 1953.

However, photos shared by a Redditor upon the PlayStation 5's release showed some PS5 boxes stated the consoles were made in China, while others were made in Japan (with accessories made in China). Sony does have branches in China, including manufacturing, although it has moved some of its production to other countries in recent years. It's likely that many of Sony's PlayStation 5 consoles and their hardware were made in China — and that even the consoles made in Japan used components that were made in or purchased from China.

How does Sony make the PlayStation 5?

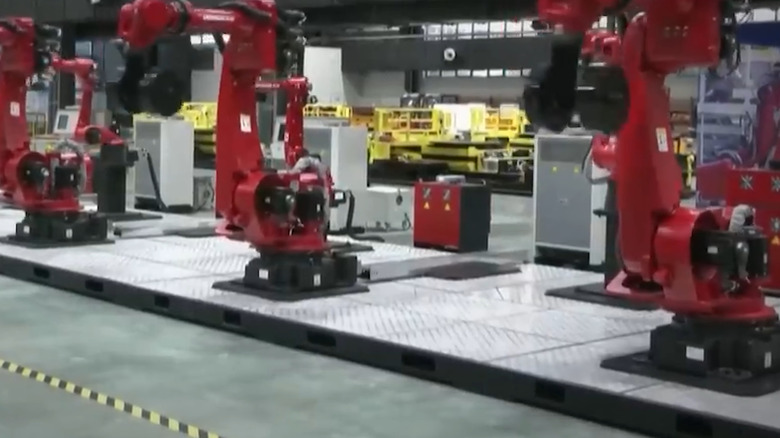

In a video for Wired, Mark Cerny, Sony's Lead System Architect, said, "The big challenge of hardware is working through the sheer number of details involved in creating a console." Engineers have to piece together the console based not just on each component's potential performance, but also on how easily robots can fit them all into the console in the factory. Sony isn't the only company to rely on robots in its manufacturing. Robots have also been used to build cars and run 3D printers.

While the Kisarazu site is considered the heart of Sony's operation, making a PlayStation 5 involves more than a thousand suppliers from all over the world. Once all the components reach the facility — whether that's Kisarazu or another location — a single PlayStation 5 can be assembled in 30 seconds. Engineers design and oversee the entire process in Sony's spotless facility, which is home to 32 advanced robots that handle the assembly. The robot arms first deal with all the wiring and cables for the motherboard, then assemble multiple CPUs, and put the custom-designed AMD chip into place to supply the console with a much-needed cooling system. Before a PlayStation 5 can leave the facility, they are put through rigorous testing. The consoles are powered on, have every port and disc drive checked, and software installed. If there are any errors, the console is flagged — and it may even be recycled if necessary.

Is Sony planning to move PlayStation 5 manufacturing due to tariffs?

In May 2025, Sony revealed that President Donald Trump's imposed tariffs on imported electronics would cost the company around $680 million. This could lead to the PlayStation 5's price going up in the United States. Sony CEO Hiroki Totoki has previously stated that the company had been considering producing the console in the U.S. to make manufacturing more efficient. In April 2025, it increased the console's price in Europe, Australia, and New Zealand. On its website, Sony said this was due to "a challenging economic environment, including high inflation and fluctuating exchange rates."

During a call to investors, Totoki stated, "There are a lot of tariffs and uncertain issues around the environment. So rather than looking at the unit sales, we want to look at the entire market and try to have a flexible approach to shipment." Sony already has some facilities in the United States, like Sony DADC in Indiana, but the company would need to make a lot of changes to make the switch to its existing precise operation.