The Cutting-Edge Engine That Could Power America's 6th-Generation Fighter Jets

The evolution of warplanes never stops. While high-tech fifth-generation fighters like the F-22 Raptor and the advanced F-35 Lightning are considered among the upper echelons of technology in aerial warfare, military planners are constantly thinking ahead. The United States Air Force's sixth-generation fighter jet concept exemplifies this. The Next Generation Air Dominance (NGAD) initiative, as the program is known, aims to ensure that the USAF remains the world's dominant air force. The clue is in the name.

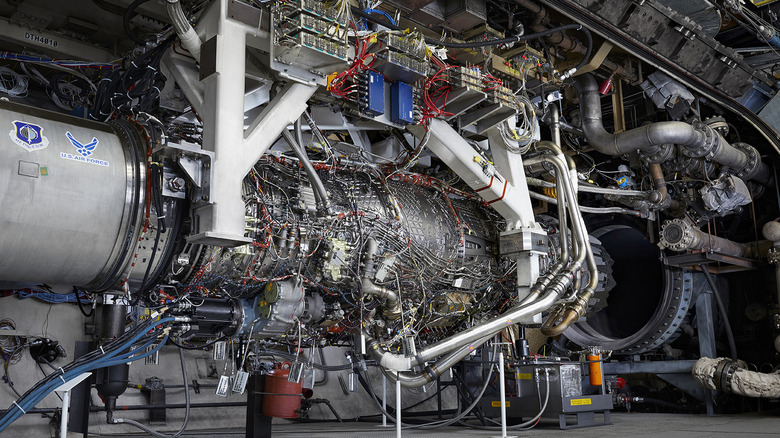

A major part of this initiative is the development of new power plants via a program known as the Next Generation Adaptive Propulsion (NGAP). Under this program, two companies, GE Aerospace (GE) and Pratt & Whitney (P&W), have been awarded $3.5 billion contracts to develop new engine prototypes. Some of the technologies incorporated in the new power plant were originally developed by the companies under the Adaptive Engine Transition Program, an initiative intended to upgrade the F-35 Lightning jet.

However, the program was shelved, and the resources were allocated to the NGAP program. The engines, known as XA102 (GE) and XA103 (P&W), are core parts of the NGAD program and are expected to provide enhanced thermal and power management, durability, and fuel efficiency. Let's have a closer look at what we know about the cutting-edge engines expected to feature in the sixth generation of US fighter jets.

Adaptability is key for the future of fighter jet engines

Fifth-generation fighters are capable of incredible speeds. Of course, all that speed needs a lot of power, and the engine is one of the pieces of tech that enables fighter jets to reach high speeds. However, all that speed and power come at a cost — fuel efficiency. This is one of the key areas that the next generation of engines aims to improve upon. The ever-changing nature of combat means fighter planes need to travel further than ever before and still have the power available when they arrive in combat situations.

Before we look at how the new engines address this, it's useful to get a grounding in how jet engines work. Modern jet engines — both military and commercial — use two streams of air to generate thrust. The core stream flows through the center of the engine, where it's mixed with fuel and combusts. The bypass stream is fed around the core and supplies additional thrust; this can be thought of like the air going through a propeller. The ratio between the air that enters the core and the air that bypasses it is called the bypass ratio. Put simply, the higher this ratio, the more fuel efficient the engine is. This is why modern passenger jets will all use high-bypass engines. For instance, the GE LEAP engine has a bypass ratio of 11:1; for comparison, the Pratt & Whitney F100-PW-100 engine from 1970 has a bypass ratio of 0.36:1.

These engines will have better efficiency and performance

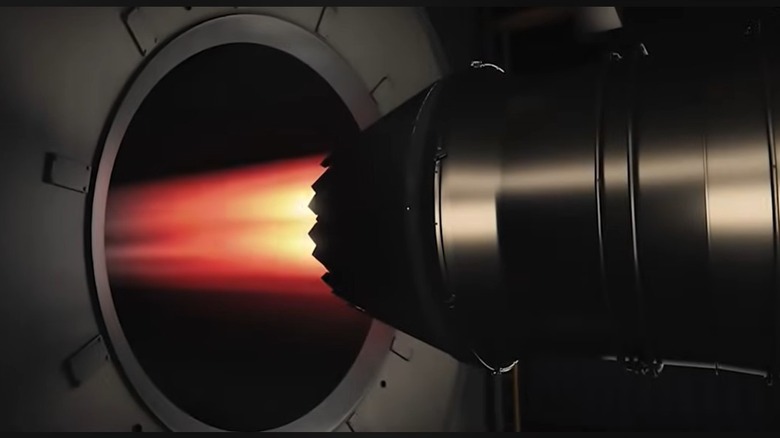

The key to these new engines is the "adaptive" part of the NGAP name, and there are several key points to note. The first is the aforementioned "adaptiveness" of the engine. This architecture allows the engine's components and parameters to adjust dynamically to suit the current requirements. One trick that enables them to achieve this is a third air stream, which allows the engine to switch between bypass ratios. In cruise mode, this stream goes around the core and increases the bypass ratio, boosting fuel economy. However, when more power is needed, the flow goes through the engine core to boost performance.

The materials used in the engines are also a critical part of the package. Key among these is the development of ceramic matrix composites (CMCs). CMCs are lightweight, robust, and can handle temperatures that are hundreds of degrees higher than traditional materials. Ultimately, it's these factors that GE says will boost fuel efficiency by 25%, improve thrust by 10% to 20%, and more than double the engine's thermal management capacity. When we can expect to see these engines in action is still unclear. P&W says it expects to test its XA103 engine in the late 2020s. GE has already fired up its XA100 three-stream engine and is using this as a foundation for the development of the XA102.