What Years Did Cummins Use The CP3 Pump?

By now, you've probably heard of Cummins, the manufacturer known for some of the best diesel engines on the market today. Granted, there are a few other engine manufacturers that are worth their salt, especially if you're seeking American-made diesel engines. However, Cummins motors, such as the mid-fourth-generation 6.7-liter and first-generation 5.9-liter engines featured in our best years for Cummins diesel engines, pack a punch. The company's products are also known to pair well with components from various manufacturers, one of which is the Bosch CP3 fuel pump. It's an efficient and equally reliable pump that saw extensive use between 2003 and 2018 and from 2021 to now.

In its early years, the CP3 paired with the third-generation 24-valve 5.9-liter Cummins engine, which had variants that could push upwards of 305 horsepower and 555 pound-feet of torque. However, as the years progressed, it would also see extensive use with Cummins' 6.7-liter motor, which is rated at 400 horsepower. Today, we examine the roots of the CP3 fuel pump and why it is highly valued by many in the automotive industry.

The common-rail system was a game changer

The Bosch diesel injection pump dates back to the 1920s, when Robert Bosch, after years of hard work, installed one into a truck. Although the installation was a success, it resulted in loud vehicles that were as much a nuisance as they were a necessary part of a developing society. The common-rail system, of which the CP3 is a part, aimed to fix this issue, resulting in quieter, more economical vehicles.

This common-rail fuel pump was created by Fiat's subsidiary, Elasis, and was successful at addressing the noise issue raised by Bosch's injection pump. However, Fiat would sell the common-rail patent to Bosch in the mid-1990s, citing Bosch's industrial experience as the main reason for the sale. Bosch would, in turn, refine and mass-produce the fuel pump, and years later, introduce the CP3.

This high-pressure, common-rail platform would become famous for its high fuel delivery and efficiency, which could be used in various vehicles, from trucks and cars to heavy machinery. They would appear in several respected engines, including the Duramax between 2001 and 2010, and the Cummins engines. Let's go over how the engine worked.

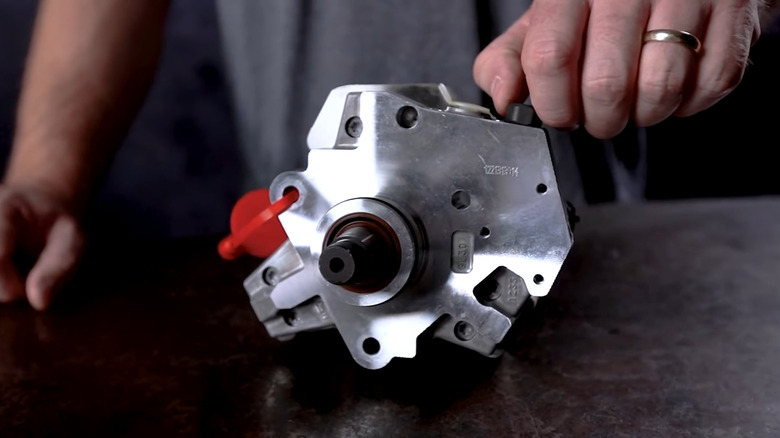

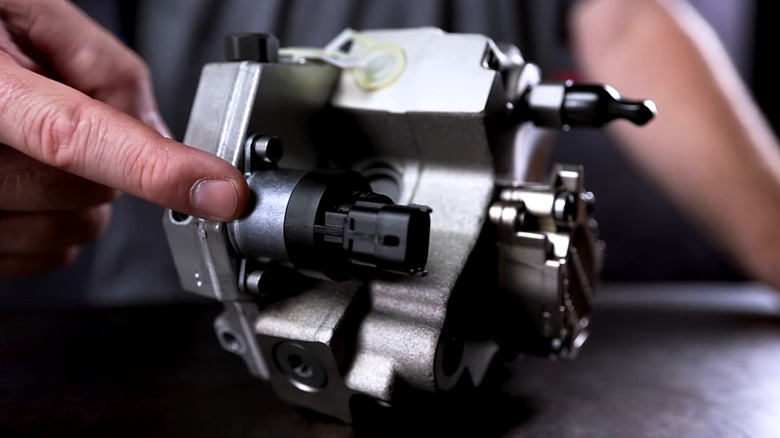

The CP3 is its own little engine

Like many parts that make up a vehicle, a fuel pump is a series of mechanical wonders that can easily be mistaken for sorcery. The pump's body houses a plunger, springs, and valves and operates like a car's engine. A simplified explanation of the pump's function is that it draws low-pressure fuel from the tank and pressurizes it before sending it to the fuel rail, which supplies it to the fuel injectors. The pump draws power from the vehicle's battery and is managed by the fuel delivery or engine control module (ECM).

Over the years that the CP3 has been around, it has established itself as a good fuel pump, so much so that Stellantis, which owns Ram alongside several vehicle brands, brought it back in 2021 for its Cummins-powered vehicles. The vehicle giant recalled over 222,000 Rams from the 2019 and 2020 model years, with one reason for the recall being the intention to install the CP3 in each.