How To Use A Wire Stripping Tool (And Which Type You Should Be Using)

We may receive a commission on purchases made from links.

Wire work is a more delicate task than some might assume. In order to make a repair or installation you must first get to the wire itself, which is hidden underneath a protective insulating layer. The wire inside is surprisingly fragile and can be easily damaged if you handle it incorrectly. While you could conceivably get through the insulation with a knife or similar tool, there are more efficient options to choose from. Easily the best and worth adding to any quality electrician's tool belt is a wire stripper.

Whether you're a professional electrician or a novice DIYer working on a project, a pair of wire strippers is an essential component to add to your tool bag. These handy items can remove the sheath from any wire with great ease and efficiency. Wire strippers are designed to be strong enough to perform such tasks while never damaging the inner wire throughout the process nor causing injury to your hands.

However, before getting one of your own, it's crucial to understand what kind of wire strippers will work best for you and how to use them. Today we'll be diving into just that, exploring the various wire stripper varieties you'll commonly find and going over how they function.

How to use wire strippers

The best tools are those that are seemingly simple in their functionality and design while expertly performing in their intended task. This description accurately fits wire strippers, as these handy gadgets are extremely easy to use while also being versatile thanks to their array of features and hidden capabilities. Depending on the kind of wire stripper you have, there may be some minor differences in how you approach the process, which we will touch upon further down. But for the most part, you can go by a similar series of steps, as follows:

- Insert the wire into the appropriate slot. Manual wire strippers typically have one or more slots of different gauges, so place your wire in between each until it fits in snuggly. Automatic strippers let you insert the wire from the side, in between the jaws, which will adjust to the wire gauge accordingly.

- Once you have your wire or cable securely in place, squeeze the handles to get a good grip on the wire. For automatic strippers, this act will prompt the jaws to both clamp down and strip the wire right away.

- If using a manual stripper, pull on the wire towards the end and remove the outer layer.

On top of their namesake stripping capabilities, most wire strippers also come with a clipper located in between the handles and jaws. This can be used to trim your wire before placing it in the stripper, if needed.

Gauged wire strippers

Wire strippers can essentially be split into two categories, with manual and automatic wire strippers. Manual strippers will require you to pull on the casing in order to remove it. Within this category, one of the most widely used is gauged wire strippers.

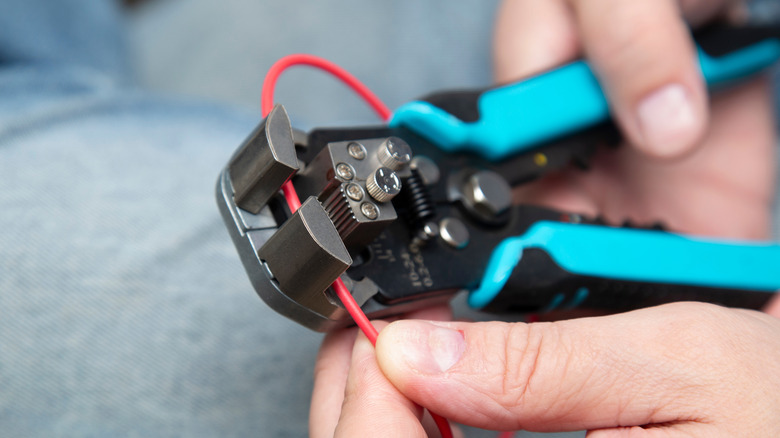

Gauged wire strippers are among the most commonly used stripper types for good reason. Their ease of use, strength, and versatility make them ideal for practically any situation or experience level. The name of these tools comes from their distinctive jaws, which feature a row of slots that look like teeth. However, rather than being used for cutting, these slots are designed to correspond with different wire gauge sizes. When you're ready to strip the wire, you locate the slot that it best fits into and insert it there before squeezing the handles and pulling off the sheath.

Gauged wires are easy to use for newcomers and are an overall great choice for most standard wire work. However, it's important to at least have an idea of the size of wire you're working with before getting one. The slots available on your respective tool are all you have to work with, so if the gauge size of your wire or cable doesn't correspond with any of them, you're out of luck as there's no way to adjust them.

Adjustable wire strippers

The other commonly used manual type of wire stripper is the adjustable stripper. These are far more simple in their construction than their gauged counterparts, but can nevertheless be a quality choice for the right kind of user and application.

Adjustable wire strippers typically have only one small to medium-sized slot to fit wire through. At first glance, it may put them at a disadvantage when compared to gauged strippers. However, what sets these apart is that their opening can, as their name implies, be adjusted to more accurately accommodate your wire. This is accomplished through the implementation of a knob located near the slot that can be used to adjust the slot's opening.

While this offers a solid amount of flexibility and convenience for average-scaled projects, these can be somewhat tricky for novices, as it can take time to accurately adjust the tool, especially if you're not used to it. For those comfortable enough with them, they can prove handy when you need to make repeated cuts to wires of the same size, after setting the gauge to the desired thickness. Like gauged wire strippers, these tools are typically far cheaper than more advanced models.

Automatic wire strippers

If estimating a wire's size and properly stripping it is too tedious, then it's perhaps best to opt for more advanced choices. Automatic wire strippers make excellent options for those seeking greater control and accuracy when going about their wire stripping.

Automatic wire strippers, also known as self-adjusting strippers, possess a unique set of jaws, typically appearing like two small hinges that sit atop the tool. This is what will strip your wire. In order to do so, you'll need to insert the wire through the side of the tool until it's comfortably under the top hinges. Many of these wire strippers also have a handy plastic guide on the opposite side of where you'll be inserting the wire. This can aid in control and ensure you have an ideal wire length. When you press the handles, the jaws will adjust to the thickness of the inserted wire and slide apart to strip off the sheath. Some models bite down on the wire in a more straightforward manner, with a cutting tool stripping the wire when you release the handle.

Thanks to their ability and efficiency, automatic wire strippers are used commonly by professionals and experienced DIYers who deal with medium to large volume tasks, especially when wires are of varying thickness. These are typically more expensive than manual wire strippers, but it makes sense if you see yours as a long term investment. For the cost-conscious, the Amazon Basics Self Adjusting Wire Stripper is an economical pick that happens to be among the brand's top-rated hand tools.

Laser wire strippers

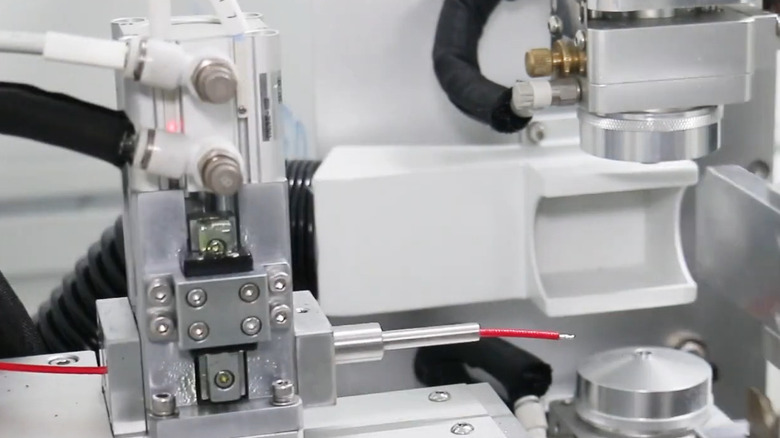

One last variety worth mentioning is laser wire strippers. These are far from the kind of wire strippers you'll find at your local Harbor Freight, as these specialized machines utilize an entirely different process to do their job that, while overkill for most hobbyists and DIYers, is essential in large-scaled professional settings.

Rather than relying on slots or special mechanisms to strip the coating from a wire, laser wire strippers rely on heat and radiation. The two most common laser varieties used to do so are solid-state and pulsed lasers. Solid-state lasers heat material using light and can be especially efficient at stripping insulation off of several wires simultaneously, while pulsed lasers emit light in short bursts. Whichever way is utilized, the delicate inner components of the wire are left unharmed by the beams. Along with delivering high-quality, precise insulation removal, laser wire strippers also leave behind less waste and are energy efficient. These qualities have made them invaluable in industrial settings, being commonly used across automotive, defense, and medical industries.