Electrical Plug Types: How Many Are There & Why Are They So Different?

Electrical outlets are likely among the most significant and overlooked devices in the common household. And, depending on where you are in the world, you may have a vastly different image pop in your head when you picture one. Some have two prongs (also called pins), others have three. Some prongs are cylindrical while others are angled, straight, D-shaped, some outlets are upside-down, and so on. What's the point of having so many variations, and why are they shaped differently?

In short, electrical outlets and their corresponding plugs are similar in role to standard rail gauge and train cars — different countries feature their own individual styles, born out of separate developments that happened to catch on. They all perform the same function: that is, completing a circuit between a power grid and the appliance itself. But the plugs themselves remain incompatible without adapters, generally-speaking. That's because various countries feature different voltage ratings and standard plug shapes, some with a third grounding prong, some with insulated components, and so on. And that's not even accounting for smart plugs and their various creative uses.

There are 15 plug and outlet designs in common usage around the world today. These use a lettering system developed by the International Trade Administration (ITA), with letters denoting the style of plug, from Type A to Type O. Some of these plugs feature more substantial differences than others, such as the Type A and B plugs only rated to 120 volts, whereas most other plugs reach 220 to 240 volts.

What the prongs do

Starting with the most commonly-found difference, some plugs feature two prongs (Types A and C) whereas all others have three. Much like a car battery, you have two main sides to every plug: a "hot" side and a "neutral" side. On the standard Type A plug commonly found in the United States, an outlet's "hot" side is on the right. These plugs commonly use different size blades so you can only plug in the device one way; this enforces the electric current to follow a specific path, called polarity.

It's similar in concept to a one-way road — flipping the plug will flip the traffic flow. This is important because appliances are designed with switches that allow specific amounts of current through. Having a reverse polarity means that the current must travel through the whole device before it hits that switch, meaning it's hot at all times. So most plugs have their blades or prongs oriented to specifically allow only one correct insertion.

As for the third prong, that's only used for grounding — it provides a path for stray electricity leaking from a product. Its primary function is to protect the internal components of its parent appliance by preventing surges and triggering the circuit breaker in the event of an emergency. It's typically only found on devices with sufficiently large power demand, such as computers and game consoles, kitchen appliances, and multi-outlet power strips. As such, some people will cut off this extra prong to fit in two-prong outlets; this is inherently unsafe and can lead to nasty electrical shocks.

Which countries use which plugs and why

During the pioneering days of electrical engineering, virtually no standardization occurred between independently developing electrical grids. Consequently, many plugs are often landlocked to specific nations or regions based on their country of origin. For example, Type A and B (two and three-pronged) plugs found throughout North America and Japan were invented by an American in 1904: Harvey Hubbell II. Conversely, the British Type G plug was invented in 1947 with British Standard 1363, in an effort to create safer universal outlets for new postwar housing.

The most common plug types are Type A and C, with the former in use throughout the United States and Japan; and the latter throughout much of Europe, Northern Africa and the Middle East, South America, and Asia. Neither type features grounding prongs, though there are variations which include such provisions. We discussed Type B previously; Type C's variations include E and F. Type E uses a grounding prong on the outlet itself, whereas Type F has indentations with conductive clips that link with the outlet to ground the appliance.

Other less common outlets are found in relatively isolated cultures, such as the Australian standard Type I plug, also found in New Zealand and China. This plug uses an inverted-V configuration for the main blades, as opposed to the typical vertical or round prong orientation. And lastly, the British Standard 1363 plug, Type G, remains in widespread use throughout the United Kingdom, Hong Kong, and the Arabian Peninsula.

Insulation and other design alterations

Several plug designs contain a number of distinctive differences aside from just the shape or orientation of the prongs. For instance, some plugs feature prongs where the prong itself is only partially-exposed; the base portion is housed in a black jacket. With electrical tape, the color black means it's an insulator; it's much the same case here. In short, these plugs prevent electric shocks if the plug isn't fully-seated.

Imagine a typical unshielded plug, like a common American or British Standard, hanging halfway out of an outlet. The circuit is still live, but there's exposed metal outside of the outlet. This carries a safety risk, especially if that surface contacts other conductive materials like metal. An insulator effectively prevents this by making it so a backed-out plug won't have any exposed metal until the plug is fully removed. Countries like Australia have mandated such designs, requiring retrofits on electrical appliances dating back to 2005.

Another design oddity relates to American Type A and B plugs — namely, the holes inside the prongs. According to the National Electrical Manufacturers Association (NEMA)'s Frequently Asked Questions publication, "The holes were originally intended to be a detent to help retain the plugs in the receptacle contact." There are still certain outlets which utilize these holes as locks, preventing the appliance from being unplugged. Likewise, one can effectively "lock" an appliance by locking a bar through the holes, preventing one from plugging it in. Such a device can, for instance, represent a factory seal to prove that an appliance was never plugged in before purchasing.

Adapters and international compatibility

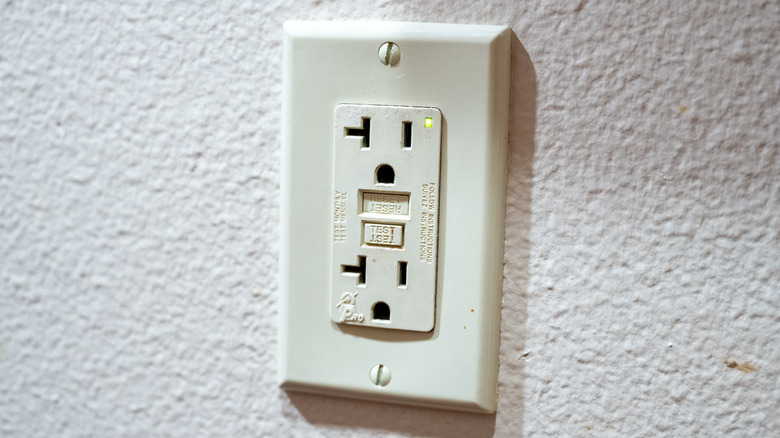

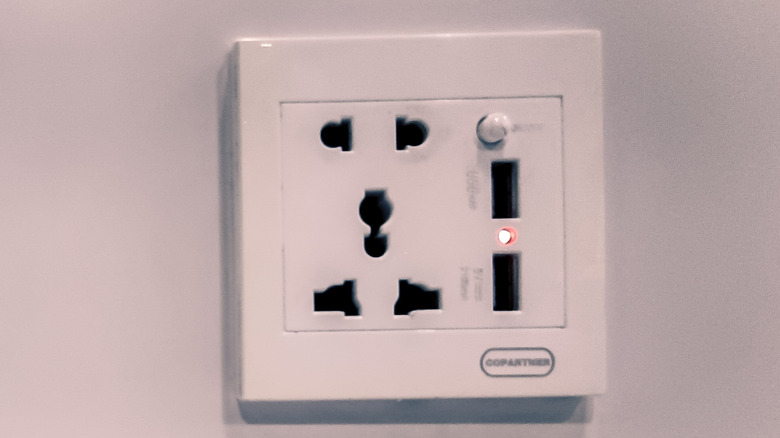

Many outlets are compatible with various corresponding plugs, such as Type A and B (American and Japanese), Type C, E, and F, and others. Some outlets feature multiple types in one single outlet, called a universal outlet or universal wall socket; these are especially common in places with international traffic like hotels. There are four common universal outlets, which use notation based on which plugs they service: Type A-C, Type A-C-I, Type A-B-C-D-E-F-G-I-O, and Type A-B-C-D-E-F-G-I-J-K-L-O.

While it might seem like the ideal solution to the issue of a lack of standardization, universal outlets actually pose inherent safety risks. In order to accept various plugs, these outlets must have any number of exposed holes, meaning it's possible to touch live pins while inserting a plug in the socket. Further, they lack any ground connection without a three-prong plug like a Type B. And lastly, having so much exposed space leads to the risk of a plug loosening due to lack of retention.

A safer alternative to the universal outlet is an adapter. Various adapters are available that convert plugs from one output to another, allowing you to plug in a Type A into a G, for instance. These plug into the regular wall socket, serving as an intermediary, and are popular with globetrotters and international flyers. Similarly, some places feature multiple wall sockets, where there are various types of outlet next to each other rather than combined. These offer the relative safety of any normal outlet without the hassle of a potentially loose connection in a universal socket.