Can You Use Dado Blades With Harbor Freight's Hercules Table Saw? Here's What To Know

We may receive a commission on purchases made from links.

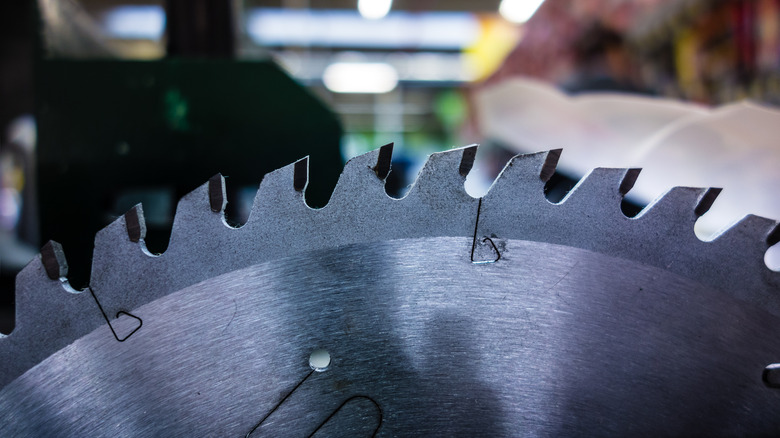

One table saw feature that's a must for many woodworkers, particularly those crafting furniture, is the ability to accommodate dado blade stacks. A dado is a special circular blade that allows you to cut wider sections of wood away in one pass. You can still accomplish wider cuts with a regular saw blade from a top brand; however, you will need to make several passes close together and then manually chip out the remaining material.

There are adjustable (wobble) dado blades, which include a thick dial that allow you to fine-tune cutting width and wobble as the blade spins, removing the desired amount of wood. Although, it's a tool you'll probably never use and can probably get rid of because of the dangers surrounding a vibrating blade. There are also dado blade stacks, which consist of multiple blades you put together and use spacers to adjust width.

Unfortunately, in the case of Harbor Freight's Hercules Table Saw, you can't use either an adjustable (wobble) dado or dado blade stack safely. The issue is that the arbor (the 5/8-inch rod that goes through the blades and holds them securely) isn't long enough. However, a single blade groover (another type of dado), which can remove sections up to ¼-inch will still fit on the Hercules, but will run you around $200 for a single blade.

Unsecured table saw blades could prove disastrous

The Hercules Compact Jobsite Table Saw includes some notable features like an adjustable fence, vacuum connection, and anti-kickback implements. However, a considerable number of compact table saws don't afford you the opportunity to use a complete dado stack kit, and this Hercules model is no exception. The arbor is simply too short once you include the washers, dado blades, spacers, and finally the locking nut.

In frustration, you might be inclined to skip one of the washers on your arbor to fit a dado stack, but its extremely ill-advised. Per FederalRegister.gov, 2015 saw over 30,000 emergency situations where an individual and moving table saw blade crossed paths. Now imagine, a situation where the washers and bolt meant to hold spinning blades secure aren't properly utilized. If the locking nut is barely hanging on to the end of the arbor, you could potentially have saw blades flying off the tool at high speed.

A short arbor and motor capacity

Smaller tools like Harbor Freight's Hercules are convenient because they can be relocated more easily than larger units, though the Mighty Mite tiny table saw takes the win in terms of portability. However, while easier to move around the job site, these compact power tools don't have the same muscle as the larger professional grade units. Not every tool can tackle the most challenging tasks, like specialty dado cuts. Therefore, the short arbor may be an intentional move on the part of the manufacturer to prevent motor burn out.

In addition to burning out the motor, there are also safety considerations when a tool is underpowered for the job. The greater the amount of wood being cut, the more power the motor must generate. According to one expert, "A table saw (or radial arm saw) must have a strong motor to handle a deep cut with a full dado set without the motor bogging down under the load. If the motor's rpm drop too far, the chance of kickback increases." Kickback is an unfortunate situation where the wood being cut can suddenly fly toward you, becoming hazardous airborne debris.