5 Essential Parts You'll Need Before Starting An LS Swap

Chevy LS engines are among the most popular donor motors for DIY swaps in vehicles from vintage muscle cars and Jeeps to 1970s and '80s sports cars. The LS series' high power-to-weight ratio, relatively compact size, and easy tunability has made it a prime choice for gearheads since it first appeared in the 1997 Corvette.

The LS engine has undergone many updates since then, and is now in its ninth generation. The LS9 used in the current Corvette ZR1 is a 6.2 liter supercharged beast that puts out 638 hp and 604 lb-ft of torque. By comparison, the LS1 generated "only" 345 hp and 350 lb-ft of torque.

No matter which LS series engine you're going to use or what vehicle you're putting it in, there are a handful of parts you're going to need to finish the job, however. As with any major DIY auto project, preparing yourself thoroughly ahead of time can save you money, aggravation, and frantic trips to the parts store. Although every swap job is different and your exact needs will vary based on the recipient vehicle, here are five essential components and systems common to most LS swaps.

Motor mounts

One of the first steps in any motor swap is to make sure you can bolt the new motor securely into your engine bay. Since LS engines are so popular as swap motors, there are a many options for third-party motor mount kits available to make this part of the job easy. Summit Racing and Quadratec sell an array of motor mount kits for LS engines that will either bolt right into or can be adapted for many vehicles, or your local machine shop should be able to fabricate a set for you if necessary.

Another good source for LS motor mount kits is Advance Adapters, which carries a wide selection of complete swap kits that include transmission, transfer case, and driveshaft adapters, radiators, and hardware kits. If you're installing a new transmission alongside your LS engine, it's possible you'll want to buy a new transmission mount along with your new motor mounts.

Fuel injection/intake

Next up, you'll want a reliable fuel injection system to get the most out of your new LS engine. If you're using a salvage yard engine, you might be able to adapt the donor vehicle's fuel delivery and other intake components to your car or truck, but you're going to inherit any problems the original vehicle may have had. Fortunately, there are many aftermarket fuel injection systems available for LS engine swaps.

Holley began making carburetors for Henry Ford in 1903 and now manufactures a broad line of electronic fuel injection kits, including the plug-and-play Terminator series of EFI systems for a variety of LS engines. Edelbrock and FITech also sell complete LS fuel injection kits, some of which come with inline or in-tank fuel pumps, oxygen sensors, and LCD screens for programming and diagnostics. Many of these kits will bolt on to a stock LS intake manifold, but some systems and vehicles will require you to purchase a manifold separately or have one adapted specially for your application.

Exhaust headers

LS engines are considered performance upgrades for most vehicles, and getting the most out of your swap and adapting it correctly to your car or truck often requires fitting it out with a custom exhaust system. Many bolt-on LS exhaust headers are available from the likes of Hooker, Hedman, and Speed Engineering. Some LS series engines use the same header configuration, but the ports on LS7 engines are slightly larger than those on the other LS heads, as are those on engines that have been outfitted with custom racing heads. If you're using one of these, you might need to use 2-inch tubes, instead of the 1-and-7/8-inch pipes that are sufficient for most LS engines.

You'll also need to make sure the rest of the exhaust system is routed to your vehicle's tailpipe in a way that the heat generated does not damage wiring, fuel lines, or other sensitive parts. Most headers are made of 304 or 321 stainless steel, although sometimes a ceramic coating is added for thermal protection and/or cosmetic reasons.

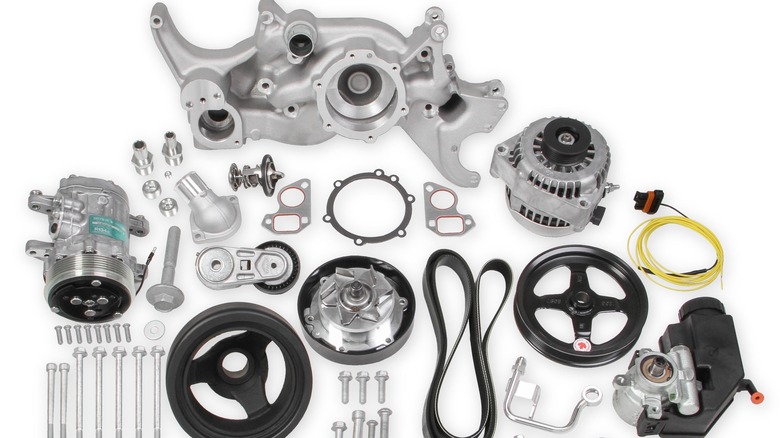

Engine accessories/brackets

Fitting front-of-engine accessories like alternators, air conditioner compressors, and power steering pumps were once the most difficult aspects of most LS engine swaps, especially in older models such as muscle cars from the 1960s and early '70s. As LS swaps became more common, however, companies like Holley recognized the difficulty DIYers were having fitting accessories easily and came up with kits like the mid-mount system that moves the belt-driven accessories well below the hoodline. This particular kit includes a relocation bracket, alternator, power steering pump, A/C compressor, tensioner, damper and accessory pulleys, and a serpentine belt.

The simplicity this offering from Holley's kit brings does not come cheap, however. It retails for more than $2,000. You can choose to piece together an accessory kit using adapter brackets and original GM accessories, but if time is money and the purpose of doing an engine swap is so you can enjoy driving your car, not that you can run endlessly back and forth to the nearest fabricator or parts store or wait for a dozen separate online purchases to arrive, then this may be what you want.

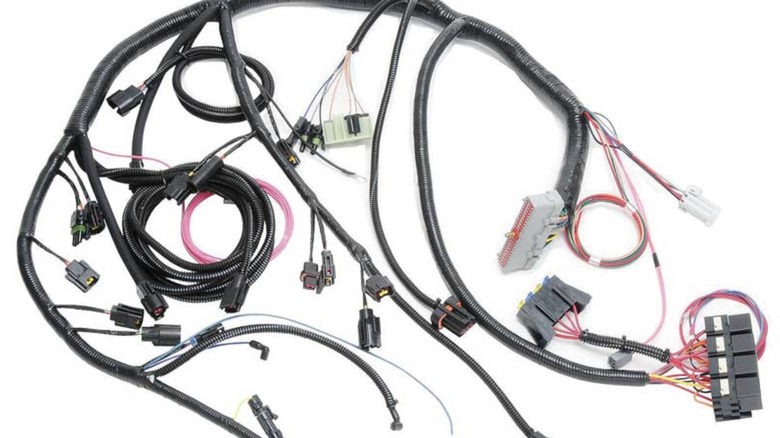

Wiring harness/ECU

Physically fitting engine accessories is one daunting challenge for any LS swapping DIYer, but getting your gauges and vehicle's other electronic systems to work properly with your new engine is another. Some older vehicles rely on analog gauges to convey information to the driver. On the other end of the spectrum, most modern engines come with a complex maze of wiring that links sophisticated digital systems.

Integrating a computer-controlled engine with an older vehicle requires adapting those analog gauges to a modern engine management system, and for this, companies like Painless Performance and Ron Francis Wiring have you covered with basic plug-and-play harnesses.

If you have a newer car or truck, you'll want to help your vehicle's existing computers communicate with your new engine's fuel, emissions, and transmission management systems. This will require a sophisticated ECU like the ones made by Performance Systems Integration, which sells complete kits for LS engines of all generations and vehicles of all vintages. This part of your swap will not only require careful planning and painstaking execution, but could end up costing you upwards of $2,000. Once again, spending good money before beginning your swap project can prevent you from having to spend even more bad money later on, not to mention how much you'll save in terms of time and frustration.