Essential Tools You'll Need When Building A Mini Engine Kit

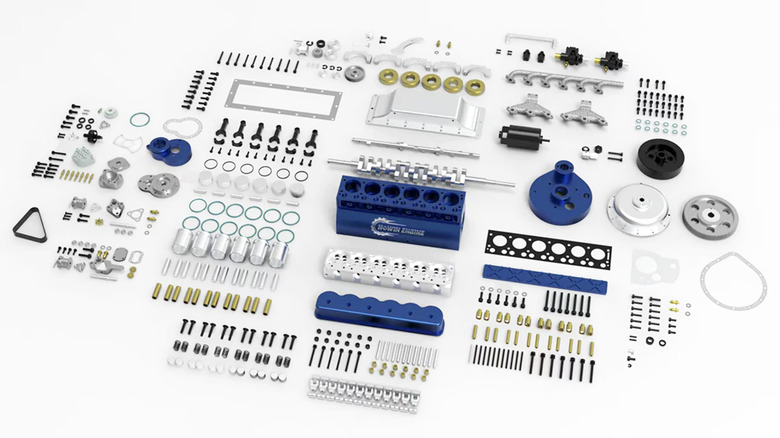

If you love the sounds and smells of an internal combustion engine but don't want to get a car to experience one, you could buy a mini engine kit and build a scaled-down example as the main feature of your coffee table. Many kits of varying complexity are available, and assembling one of these tiny engines can be a very rewarding and educational experience, no matter how old you are.

Even if you lack mechanical knowledge or experience, building a mini engine is a great way to start on that path. However, even if you're willing and eager to build one, you will still need a few things to make it possible.

The most basic requirement is a space where you can build it. This would ideally be a workbench in your garage, a shed, or someplace where you can leave parts and tools lying around. The space also needs to be well-lit (so that you see and don't lose the many small parts that go into the engine), and it also needs to be well-ventilated if the engine you're building is designed to run on liquid fuel (you won't want exhaust gases building up in the room).

Only Basic Tools Needed

Building a mini engine is similar to assembling a full-size one. The big difference is that you need far fewer specialist tools and equipment. You will need a few screwdrivers of varying sizes (both Phillips and flathead), although they won't have to be too big since most screws on a mini engine are quite small. It would be recommended to have magnetic screwdrivers, as that would make keeping all the minuscule screws in place much easier while they're being fastened. You will also need a small socket set, some open-end and adjustable wrenches, both regular pliers and the needle-nose variety, tweezers, and a set of Allen keys.

Most mini engines require you to solder a few wires to power various ancillaries. Soldering seems like the most difficult technical skill you will need for one of these projects, but all you need is a steady hand and a bit of practice, and the chances of you causing damage to your mini engine with a soldering iron are slim.

Once all your connections are soldered and secured, you will also need a multimeter to ensure the electrical connection functions within the parameters. The multimeter can provide a lot of information, but you will only need to know the basics for this application, such as current, voltage, and resistance.

Safety Kit and Consumables

Wearing eye protection is advisable when working on tiny engines with components such as springs that are dangerous, even if they're small. Any component that sits under tension is a potential hazard for your eyes. You will also need some protection for your hands. Latex gloves won't do the trick when working with metal components, so you should find a pair of light mechanic's gloves to keep your fingertips out of harm's way.

If you have a mini engine capable of internal combustion, then you will need to source some fuel for it (usually alcohol or regular fuel). You may need a small battery for it to run (although not all mini combustion engines require one), and you will also need lubricants, just like in the full-size version. You won't have to change the oil in your running combustion mini engine too often, though, as you're probably not going to run it enough to affect the quality of the oil.