If You're Buying A Mazda RX-7, Know These Things About The Rotary Engine

Every once in a while, a revolutionary new design or concept takes the automotive industry by storm. In the 2020s, it's been electric vehicles, but just a few decades earlier, the rotary engine was all the rage. Mazda was, and still is, the biggest name associated with the rotary engine, using it for over 50 years in iconic vehicles like the RX-7 and RX-8.

If you've been paying attention to the automotive industry at all, you'll know that the rotary engine didn't catch on at all like some had hoped it would. That doesn't mean it didn't earn a cult following, though. The rotary engine is a unique piece of automotive kit thanks to how it works.

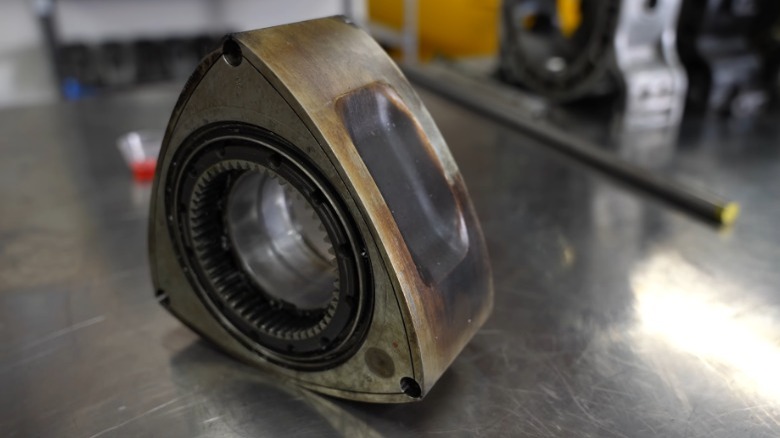

Instead of linear piston motion that's transformed to rotational motion via a crankshaft, the pistons — or in this case, the rotors — themselves connect to the crankshaft and follow an elliptical trajectory through the housing. The change in packaging makes the motor very compact, and the elimination of reciprocating motion results in an engine that loves to rev it out.

Fans of vehicles like the Mazda RX-7 love the compact, high-revving rotary engine for good reason, but it's important to know that it's not without its failings, either.

What makes the rotary engine so good?

The ever-popular third-generation RX-7, also known as the RX-7 FD, was produced between 1992 and 2002, and came equipped with a twin-turbo, twin-chamber rotary engine that produced in the region of 250 horsepower, depending on the region. Reviews, like one produced by Evo, praise the RX-7's twin-turbo motor for its snappy response and smooth power delivery, as well as the healthy power surge through higher revs.

Despite only being a twin-cylinder engine, the rotary motor found in the RX-7 FD was capable of keeping up with much of its contemporaries; with a top speed of 154 mph and a claimed 0-60 mph time of just 5.4 seconds. The rotary engine on the RX-7 is also a perfect platform for modification and tuning. Some owners, like the example on Road and Track, got upwards of 400 horsepower out of an engine originally designed to produce only slightly more than half that.

In 2020, Mazda announced that it was restarting previously-halted production of 30 different spares for the second and third-generation RX-7 models with the intention of keeping more of the cars on the road. It should also be noted that these spares are only available to Japanese markets initially, which might make maintenance challenging.

Why you might want to hold off on buying a rotary-powered RX-7

As you may be able to tell, rotary engines never quite caught on like Mazda and RX-7 fans thought they might, and there are good reasons for their absence in the wider automotive space. One of the biggest problems Mazda RX-7 owners faced was reliability, stemming from a few key issues relating to the rotary engine.

As demonstrated by Rob Dahm on YouTube, Mazda's rotary engines suffer from issues relating to the engine seals, which results in coolant and oil getting into the combustion chamber, causing poor ignition, engine knock, and rusting components. While that's bad enough on its own, the RX-7 engines also suffer from poorly-designed apex and corner seals.

Both the apex and corner seals have a tendency to degrade and break off, eventually entering the chamber and causing significant damage to both the rotor and the housing. The rotors also have a tendency to develop chatter at certain engine frequencies when the oil wasn't reaching the apex seals correctly — a phenomenon that caused damage to the rotary housing, requiring re-surfacing to correct.

Rotary engines are known for incomplete combustion, oil consumption, and high emissions, relegating the RX-7 to project car status rather than daily drivers. As Hagerty reports, somewhere around 13,879 third-generation RX-7s were sold in the U.S. between 1993 and 1995. That means finding a donor car for spares might not be easy, since they were a popular vehicle for modification.