Is A Resin 3D Printer Worth It?

When most people think about 3D printing, they probably imagine an FDM (fuse deposition modeling, or fused filament fabrication) printer — a thin plastic filament feeding through a hot extruder that moves over a bed to deposit material layer by layer to eventually build a part. If you're considering hopping onto the 3D printing bandwagon, though, you might be aware that FDM printers aren't the only game in town. You may even have seen a few resin 3D printers online, and if you've done any reading, you'll know that resin 3D printers tend to offer far more detailed prints.

While that's true, there's a lot more nuance to it than just detail and accuracy. Resin printing is similar to FDM printing in a lot of ways, but there are major differences that make resin printers excel where FDM printers lack. Knowing the strengths and weaknesses of resin printing and how they apply to what you'll be printing is key when you're evaluating which type of printer to buy.

What is a resin printer?

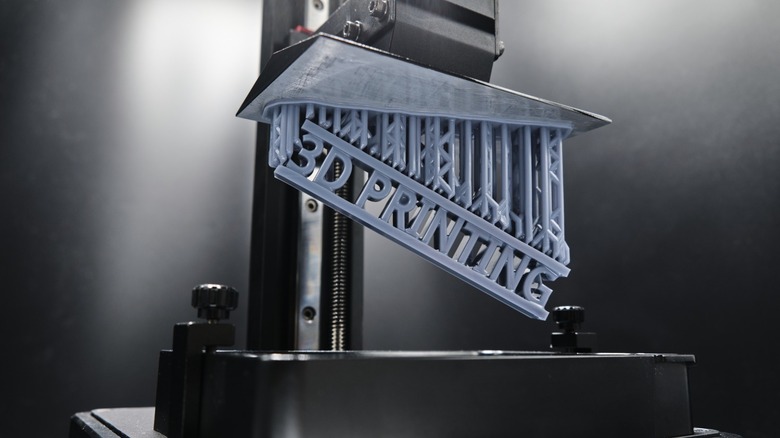

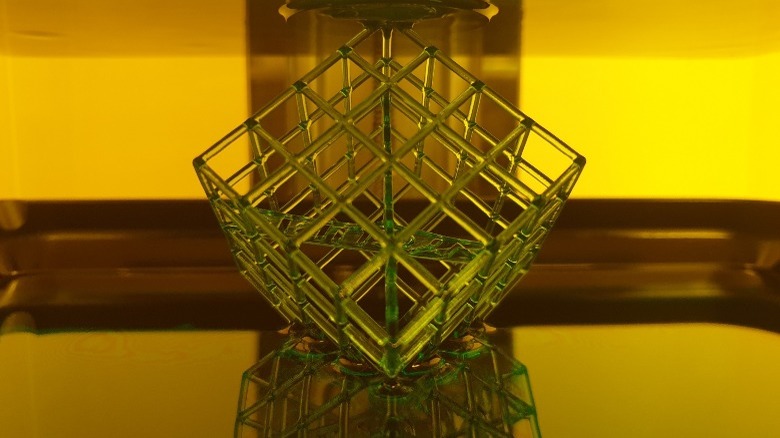

Resin printers work similarly to FDM models in the sense that they build material layer by layer — that's where the similarities end, though. As explained by Formlabs, resin printers make use of light-sensitive resin — usually as a liquid in a bath or tank, but there are printers that apply the resin layer-by-layer with a roller or a jet — and a light source to cure the resin. The type of light source can differ, as well.

Stereolithography (SLA) uses a directed UV laser to cure one spot at a time and trace out a layer before moving on to the next layer, while digital light processing (DLP) and liquid crystal display (LCD) printers use projectors and mirrors or an LCD mask and light source to cure an entire layer at a time before advancing to the next layer. Regardless of which type of resin printer you use, the printer creates one very thin layer at a time, then moves the piece vertically before starting on the next layer. In most cases, once the print is complete, the piece needs to undergo additional curing, either by exposure to UV light or moderate heat.

Why choose a resin 3D printer?

Resin printing — particularly SLA — is one of the oldest and most mature 3D printing technologies around, which means the process is quite refined by this point. This gives resin printers a few key advantages over their FDM competition. The most important advantage of resin printers is their high resolution and detail. Because resin printers use light to cure a bath of resin, they can produce incredibly detailed parts in comparison to an FDM printer.

A prime example is the 0.1-millimeter accuracy of the $499 Anycubic Kobra Plus to the 10 microns (0.01 millimeter) accuracy of the $529 Anycubic Photon Mono X — the resin printer is around 10 times as accurate as a similarly-priced FDM model from the same company. Along with increased accuracy, DLP and LCD printers have a slight speed advantage over FDM printers because they can cure a whole layer at once instead of tracing it with an extruder head — though resin printers lose a little bit of the advantage because prints need to be rinsed and cured after the printing.

In a similar vein, supports are another big advantage for FDM printers. Because part of the weight of the printed object is suspended by the liquid resin, supports don't need to be nearly as strong as they do with FDM printers. What's more, you usually don't need as many supports when printing with resin. Fewer, thinner supports mean that parts printed in resin are much easier to clean than FDM printers. Resin printers don't come without their disadvantages, though.

Is resin printing more affordable?

Running costs are a serious consideration when you're buying a printer, especially if you hope to generate income from it. Generally, your biggest expense in 3D printing is going to be resin or filament, but resin printers sometimes have consumable parts that might need to be replaced more quickly than their FDM counterparts. For example, in our review of the Phenom by Peopoly, we noted that its LCD had a lifespan of around 400 hours and cost $100 to replace.

On to the discussion of material costs, Anycubic sells 1 kilogram of UV resin for anywhere from $22 to $69.99, while PLA at the same site comes in at $21.99 to $26. At first glance, it seems like the value proposition leans heavily in favor of the FDM printer, but because resin printers use less material on supports, things even out a bit. With that said, when it comes to the initial investment, FDM printers far outclass resin printers.

The Creality Ender 3 — a reliable entry-level FDM printer — sells for $189 and is regularly on sale for around $160. On the other hand, the similarly-sized Creality HALOT-LITE retails at a whopping $579. To add insult to injury, curing and washing machines — which are not essential, but definitely recommended to get uniform prints — are often upwards of $200, as well. Even if running costs were a wash, the gulf in initial investment between FDM and resin printers means FDM printers definitely present better value than their resin alternatives.

Who should buy a resin 3D printer?

While FDM printers like the Anycubic Kobra Plus often print with materials like PLA, PETG, ABS, and even more exotic materials like carbon-fiber-filled nylon or flexible TPU, material options for resin printing are more limited, with only a handful of options to choose from (via Hubs), and few of them are ideal for practical use beyond prototypes. Another important material consideration is storage. Since the resin is sensitive to light and heat, it needs to be stored meticulously, otherwise, it could be rendered useless.

Build volume also gets in the way of the practicality of resin 3D printers. Where many inexpensive FDM printers offer around the 300 x 300 x 315-millimeter build volume, you're more likely to find a resin printer offering 165 x 72 x 180 millimeters of build volume.

Al-in-all, whether resin printing is worth it depends on your specific needs and budget. If you're looking to print strong, functional parts that need to weather the elements, you may want to look elsewhere. Resin printers excel at printing small, high-detail, non-functional — or, at least, non-load-bearing — prototypes of miniatures, action figures, or even jewelry. You can also put resin printers to fantastic use to make highly detailed molds or patterns for investment casting of jewelry or die-cast parts. If you're looking to dip a toe into the world of resin printers, we found the Anycubic Photon M3 to be very beginner-friendly in our review.