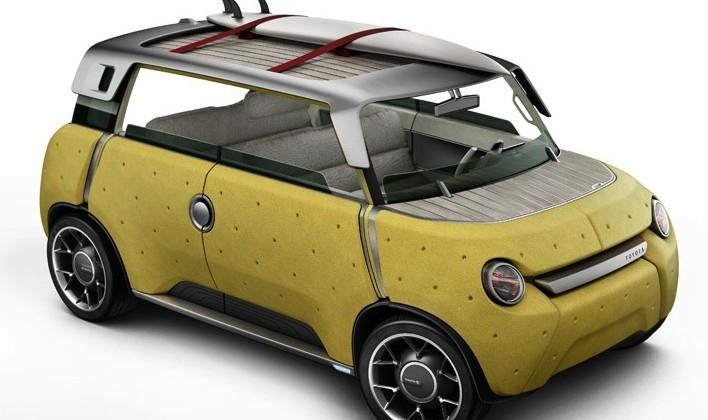

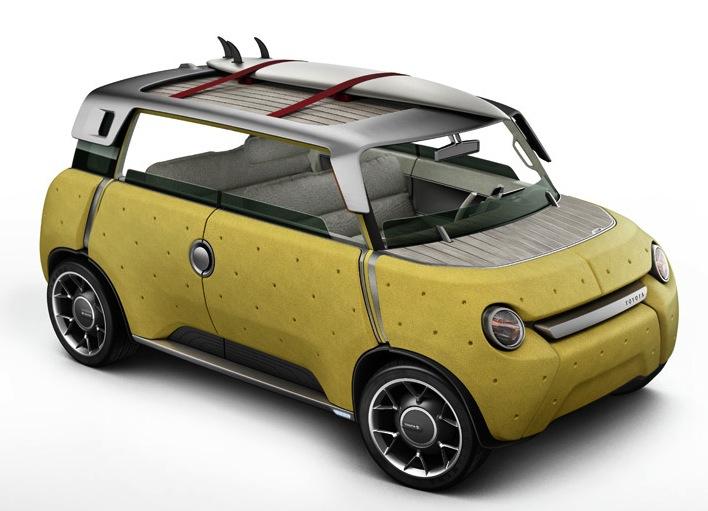

Toyota ME.WE Concept Clads EV In Chunky Plastic

Toyota has revealed a new EV concept that prioritizes flexibility, eco-concern, and easy damage repair, the ME.WE, cladding a simple aluminum sub-frame with easily interchanged polypropylene body panels. The electric car concept, designed in association with French firm Jean-Marie Massaud, can flip instantly between two- or four-wheel drive, thanks to an individual motor in each wheel, while the doors, bonnet, bumpers, wings, and other components can be switched out to suit different use-cases or to swiftly repair damage.

The core of the ME.WE is a structure made up of tubular aluminum, onto which Toyota and the design firm have predominantly applied two types of material. For the bulk of the shell that's expanded polypropylene, which has the benefit of being lightweight as well as entirely recyclable; other surfaces, such as a panel under the windshield and across the roof, are bamboo, which is known for being highly-sustainable.

Toyota envisages different colors and textures of panels to be offered, encouraging drivers to switch over their car's appearance at will. That's something we've seen Smart offer on its city-car, though exactly how many owners actually take advantage of that – outside of making damage repairs – remains to be seen.

Inside, the bench seats are fixed on slender rails and can be moved around or laid flat; the rear bench can be folded and pushed under the front seats, increasing the bamboo-clad load area. Rather than have a permanently large trunk, the ME.WE uses a combination of flexible neoprene covers – which can stretch to accommodate things transported on the roof – and integrated webbing that keeps suitcases and the like in place.

As with any concept, the likelihood of Toyota actually putting the ME.WE into production is something we wouldn't recommend holding your breath for. Nonetheless, the idea of shifting the electric motors into the wheels – rather than inboard, as per most EVs and hybrids – is one the car industry looks to be moving toward. Earlier this year, specialist Protean announced plans to mass-produce such a motor, which with clever software management could dynamically adjust the power to each wheel independently while also freeing up space in the cabin and chassis.

[via Designboom]