Stanford University Makes A Flexible Electronics Breakthrough

Scientists around the world have been conducting research into flexible electronics for many years. The goal of flexible electronics is to create devices that move and bend without breaking and could prove particularly useful for wearable electronics. Researchers at Stanford University have now developed a manufacturing technique able to produce flexible, atomically thin transistors less than 100 nanometers in length.

100 nanometers is several times smaller than previous techniques allowed. Researchers on the project have called their advance "flextronics." The promise of flexible electronic devices includes being bendable, shapeable, and maintaining energy efficiency. Flexible circuits could be used in wearable devices or implanted inside the human body for health-related needs.

Flexible circuits also promise to be very useful for small Internet of things devices. One major engineering challenge the team had to overcome was forming the thin and flexible electronics without using heat that was too high for the flexible plastic substrates. In prior methods of production, the flexible materials melted and decomposed during the production process.

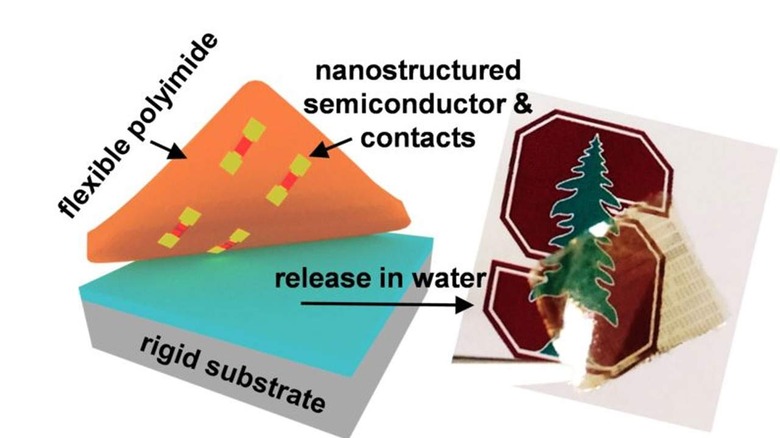

Researchers on the project developed a technique that happens in steps starting with the basic substrate that is inflexible. Devices are built on a solid slab of silicon coated with glass where an atomically thin film of the 2D semiconductor molybdenum disulfide is laid over nano-patterned gold electrodes. Since the step is performed using a conventional silicon substrate, the nanoscale transistor can be patterned using existing advanced patterning techniques.

The team can achieve a resolution that was impossible on plastic substrates. Chemical vapor deposition can grow a film of molybdenum disulfide one layer of atoms at a time, and the resulting film is three atoms thick. The process requires temperatures reaching over 1500 degrees Fahrenheit to work compared to the previous flexible substrate that required temperatures around 680 degrees Fahrenheit but decomposed at higher temperatures.

The team completes additional fabrication steps and ends up with flexible transistors capable of several times higher performance than any that were produced using prior methods. The team believes entire circuits could be built and transferred to the flexible material, but complications with subsequent layers make additional steps after the transfer necessary. Overall, the entire structure is five microns thick, including flexible polyamide, about five times thinner than a human hair.