3D Printing Saves Lives In Coronavirus Supply Line Breakdown

As supply lines break and effects of novel coronavirus (COVID-19) become real, non-traditional fixes for problems have begun to appear. One Northern Italy hospital needed valves for a "reanimation device" on Friday of last week due to an extreme up-tick in cases thanks to COVID-19. The supplier of these parts had no way of getting fast replacements. A local 3D printing group stepped up and made the possibility of quick resupply a reality.

Milan-based 3D printing group The FabLab was contacted on Friday by Nunzia Vallini, editor of the Giornale di Brescia, who informed the group that their services were needed. The founder of The FabLab, Massimo Temporelli, spoke with a number of FabLab locations and 3D printing companies in Milan and Brescia (location of the hospital itself).

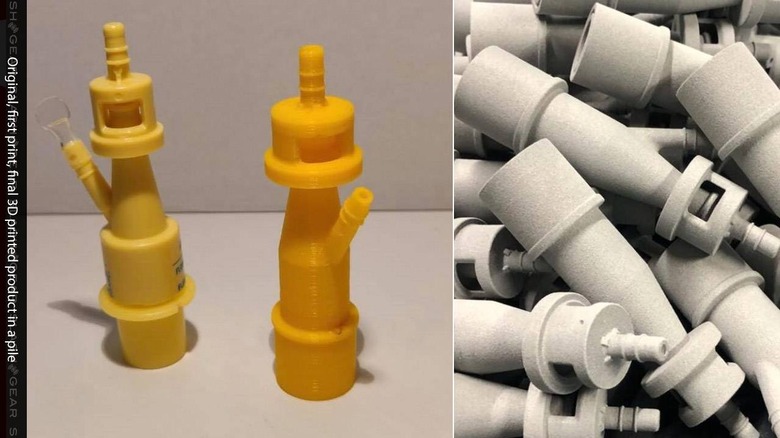

The company called Isinnova responded to the call. Isinnova founder and CEO Cristian Fracassi brought a 3D printer to the hospital. Fracassi measured the original valve, recreated the valve with 3D software, and printing commenced. The first test valves were printed with a filament extrusion 3D printer – shown here in yellow.

After the initial parts were printed, another company stepped up to the plate to create the valves in bulk. The company Lonati SpA worked with a polymer laser powder bed fusion (3D printing) process to recreate the valves with a custom polyamide-based material.

As the publication 3D Printing Media shows, the 3D printing community is ready to roll. "So many have reached out to offer help in producing these parts, both locally and globally," said 3DPBM writer Davide Sher.

"Hospitals may have a right to produce these parts in an emergency (as in this case) but, in order to legally obtain a 3D printable STL file, the hospital that requires the parts needs to present an official request," said Sher. "We will continue to update this article as new information becomes available." Tap the link above if you believe you can help (if you live in Brescia or nearby).