What Are Those Large Flaps On The Back Of A Semi-Trailer For?

If you've ever driven behind a semi-truck on the highway, you've probably noticed the huge, wing-like panels or flaps that extend behind the trailer doors. If you didn't know any better, it would seem like the trailer doors are wide open, from a distance. It's only when you drive closer that you'll realize they are mounted on the back of the trailer doors.

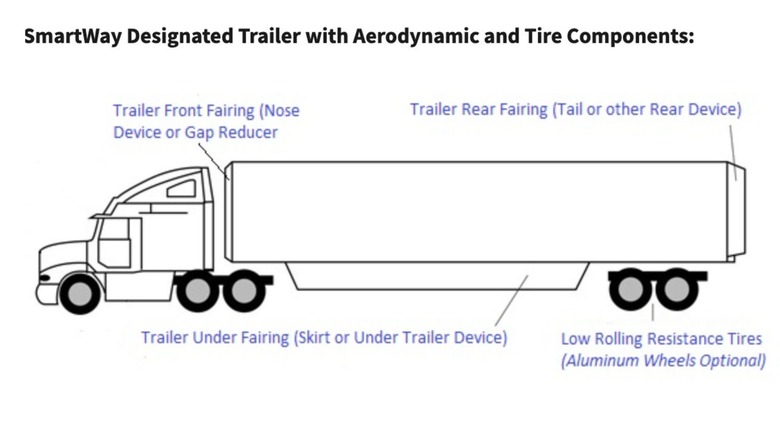

Those huge flaps or panels at the back of a semi-truck are called "trailer tails" or "rear fairings." Think of them like the massive wing on the classic NASCAR Plymouth Roadrunner – they serve the same purpose. These aerodynamic devices have become increasingly common on modern trucks.

As a truck moves at highway speeds, turbulence and low pressure build up behind the trailer, creating significant drag. The large flaps at the back of the trailer doors help streamline airflow, reducing drag and allowing the semi-truck to drive more efficiently. Semis with trailer tails have better fuel economy and reduced strain on the engine, especially during long hauls at high speeds.

How do rear trailer flaps work?

Just like a fighter jet defies gravity thanks to its massive wings and design, trailer tails work to reduce drag and help the engine run efficiently. When a truck is rolling down the road at highway speeds, the large, flat rear surface creates a vacuum, or low pressure, behind the semi-truck. This situation sucks air back and increases drag.

The flaps on the trailer may seem unusual, but they serve to streamline turbulent airflow by narrowing the trailer's rear exit zone. The trailer tails reduce the vacuum formed and, in effect, minimize the drag, which increases fuel efficiency by up to 6%. To maintain highway speeds, vehicle drivers have to press the gas pedal to get more out of the engine. If there's a lot of drag, the engine will need more horsepower to maintain cruising speeds, straining the engine. Trailer tails streamline the airflow, reducing the extra workload caused by drag.

According to the United States Environmental Protection Agency (EPA), semi-trucks that implement SmartWay (by featuring approved tires and aerodynamic devices, such as trailer tails) can save up to 4,000 gallons of diesel fuel per truck annually. This not only reduces fuel costs for trucking companies but also helps reduce CO2 emissions.

Trailer tails are a game changer in the trucking business

It's hard to believe how significant the impact of aerodynamics is on reducing operating costs for the trucking industry. The largest expenditure for these companies is employee wages, closely followed by fuel costs. According to a study by the American Transportation Research Institute, fleet companies spend 24% of their total average costs on fuel (compared to 32% on their workforce). If installing simple trailer tails can save up to 4,000 gallons of diesel a year per truck from reduced engine demands, think about how that translates into reducing operational costs.

There's more to poor fuel economy and engine maintenance than bad driving habits. The more the engine strains, the more stress is put on its internals, leading to more frequent maintenance. By reducing aerodynamic drag, the semi-truck engine doesn't need to work as hard to maintain cruising speeds. This not only improves fuel efficiency but also reduces wear and tear, ultimately extending the engine's lifespan, especially for high-mileage hauls.

According to the EPA's SmartWay program, more than 50% of new trailers in North America use some form of aerodynamic device (skirts or rear fairings). In fact, many trailer manufacturers include mounting brackets for them straight from the factory. This move isn't just about reducing operational costs for fleeting companies, but also goes a long way in reducing semi-trucks' carbon footprint by several tons annually (per truck).