How Much Would A Completely American-Made Car Actually Cost?

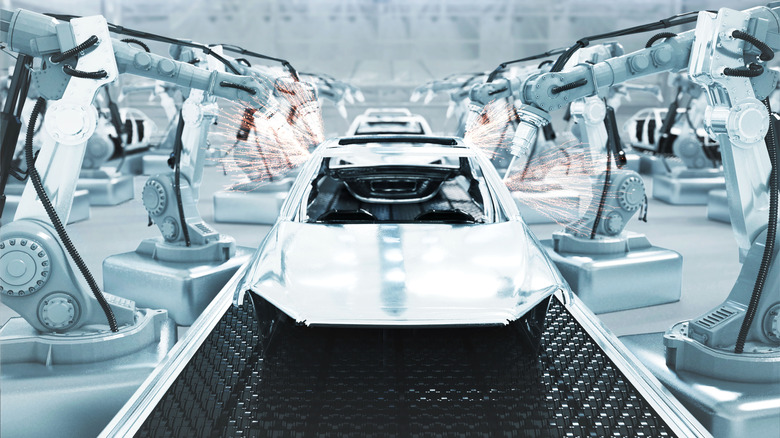

Walking into a dealership and asking for a car that's entirely American sounds patriotic, right? We are talking about every bolt, every wire, every chip, built and sourced right here in the U.S. Well, the truth be told, such a car doesn't actually exist. And honestly, it's not because automakers aren't trying hard enough. It's because the way the industry works today just makes it nearly impossible. Even cars that are assembled on American soil are built using parts that come from all over the world.

In fact, the average car today is a true global puzzle. A typical vehicle is made of about 20,000 individual parts, and many of those are sourced from over 50 different countries. Some parts even cross borders multiple times before finally landing in the assembly plant. Even the Ford Expedition, proudly assembled in Kentucky, only uses about 42% U.S.-made parts. As Jim Farley of Ford put it to CNBC, "We can move everything to the U.S., but if every Ford is $50,000, we're not going to win as a company." America imports 8 million vehicles a year, making up half of all U.S. car and light truck sales. Long story short — the current situation just makes it harder than it looks.

The price tag of going 100% American

Let's imagine building a car using only parts made in the U.S.– how would that turn out? Right now, the average new car in America costs about $48,000, according to Cox Automotive. But once you start using only American-made parts, that number climbs fast. Cars assembled in the U.S. already cost over $53,000 on average, and they're not even fully American-made. If the parts and materials alone normally cost around $30,000, switching to all U.S. parts could easily add another $10,000 to $20,000. As auto expert Mark Wakefield told CNBC, "The cost gets quantumly more the closer you get to 100%." So while it sounds like a great idea, the economics just don't work out, at least not for the average buyer.

Why the steep jump? A big part of it is supply chains. Many components, especially fasteners, chips, and rare earth materials, just aren't manufactured in large enough quantities in the U.S. Even if automakers wanted to build every part domestically, it would take 10 to 15 years to create new supply chains. That includes massive investments in factories, workers, and infrastructure. And let's not forget: some materials used in cars, like platinum and palladium, are only mined in other countries.

Being built in America doesn't mean it's fully American

If you really wanted to build an all-American car, it's not impossible, just wildly impractical. You'd have to do it in small volumes, probably by launching a niche brand that's very different from what we see today. In that case, Mark Wakefield estimates that "you could make $300,000–$400,000 vehicles that are all-American", but clearly, that's not something most people would be lining up to buy.

Plus, the line between "American-made" and "assembled in America" is blurrier than most people realize. Many flex their patriotism by driving a car made in a U.S. plant, but that vehicle might still have more than 50% foreign content. Even the label "American-made" can include Canadian-sourced parts. So we can clearly say that it's not just about where it's built, but about where all the pieces come from. Some of the most affordable models on the market — like the Hyundai Elantra, Kia Forte, and Nissan Sentra — are built overseas, making it even harder to buy American if you're on a tight budget.