6-Point Vs. 12-Point Sockets: What's The Difference And Which Is Better To Use?

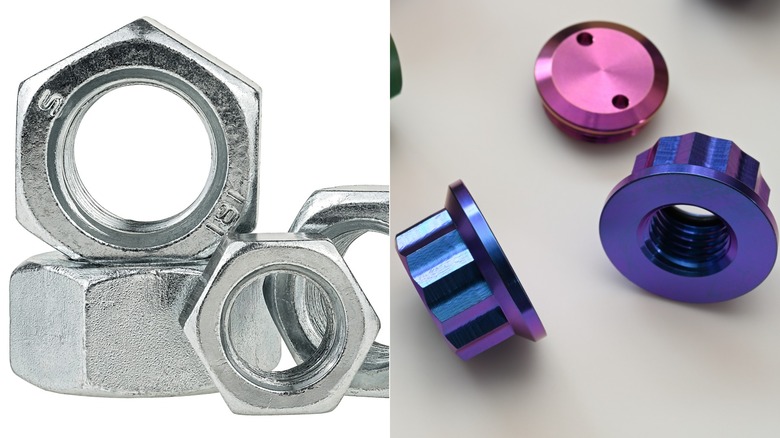

The difference between 6-point (above left) and 12-point (above right) sockets is the six extra points found in the 12-point socket. The good news is that just about every major socket set brand includes both types in a set of sockets. The bad news is that some situations require a decision about which one you should use.

A 6-point socket is easy to envision, especially if you studied geometry at some point in your life, since it's a hexagonal shape designed to fit a hex-head bolt or hex nut. Its six points lie evenly spaced around a circle, with 60 degrees separating each one. The size of the 6-point socket, whether it's in fractions of an inch or metric, is determined by the approximate measurement between the parallel flats inside the socket.

While a 12-point socket will fit the size fastener it's labeled for just as a 6-point socket will, you cannot measure between internal parallel flats because they're absent in the 12-point variety. The 12-point socket, sometimes referred to as a double-hex, has its points equally distributed around a circle spaced at 30 degrees instead of 60. This gives it more points, but the sides cannot extend between the points like they do in the 6-point socket.

Are 6-point or 12-point sockets better?

Trying to decide which is better between 6- and 12-point sockets is like comparing Phillips and slotted screwdrivers. Sure, the Phillips screwdriver is easier to use, unless the screw you need to turn is slotted. Likewise, you can use a 12-point socket on a hex-head bolt or nut, but you cannot use a 6-point socket on a double-hex, or 12-point, fastener. For reference, 6-point hex nuts are shown above on the left, while blue-anodized 12-point double-hex nuts are on the right.

That scenario might lead you to think that 12-point sockets are superior. While it's true that they provide a more universal fit, they also have less surface contact on a hex fastener than a 6-point socket. The lower contact can lead to rounding the corners of a hex fastener, especially if the fastener is particularly stubborn or made of soft material. In real-world applications, rounding the points on a fastener is more likely than encountering a 12-point fastener, so you might think that 6-point sockets are the best.

If you think 6-point sockets are better than 12-point varieties, you'd be correct, most of the time. However, sometimes having twice as many chances to orient the socket so it fits the hex of the fastener is an advantage, especially in those hard to reach areas that require you to feel your way rather than see it clearly. This back and forth pros and cons is probably why most socket sets include both 6-point and 12-point sockets.