A Closer Look At The Cybertruck's Modular Wiring System

For all of the criticism Tesla receives, credit should be given for some of the innovations it has brought to the automotive industry. The Cybertruck, for example, is billed as the go-anywhere, do-anything electric vehicle, but all of the consumer-facing marketing really fails to touch on one of the model's most significant contributions to the automotive industry—a 48v electrical system.

While the increased voltage, up from the standard 12v system, is a considerable upgrade with many benefits, it's only part of a solution to an often unspoken problem. Cars are getting heavy, and a big part of the problem stems from the current method of wiring these complex electrical systems. While the 48v electrical system isn't new, per se, it can help reduce some of this load with thinner wires, but there's still a matter of how cars are being wired.

In 2019, Tesla filed for a patent for a modular wiring system that could revolutionize the automotive industry, reducing production times and costs while cutting down on the weight of the finished product.

Solving the Problem of Autobesity and Elaborate Wiring

If you bisect a car, you'll find a nervous system of wires coursing throughout. Not too dissimilar to the human body, these wires keep your vehicle's components working, and if one is severed, an entire system will shut down.

The problem car manufacturers face is as vehicles become more advanced, they require more or thicker wiring. Older vehicles have been comprised of fewer electrical components than newer models. Power windows, power locks, climate control, power steering, lighting, and the radio are among the most common, but as cars become more advanced, so, too, do their electrical systems.

In simple terms, each of these systems is part of a network of inputs and responses, just like a home computer. The user inputs a command, like lowering the window, and a sensor pings a central controller that communicates with the window actuator. This distributes power and the response needed to move the glass downward. With the current system, there's wiring from the window sensor to the central controller, which then connects to an actuator. Extrapolate that process to every sensor in a car, and you have miles of wire in one vehicle.

As wires have gotten thicker and more abundant to accommodate the 12v system, it's contributed a phenomenon known as car bloat that's impacting the financial and environmental cost of vehicles. Tesla's modular wiring across a 48v system aims to reduce wire bulk and simplify how components communicate with the central computer.

Dissecting Tesla's Modular Wiring

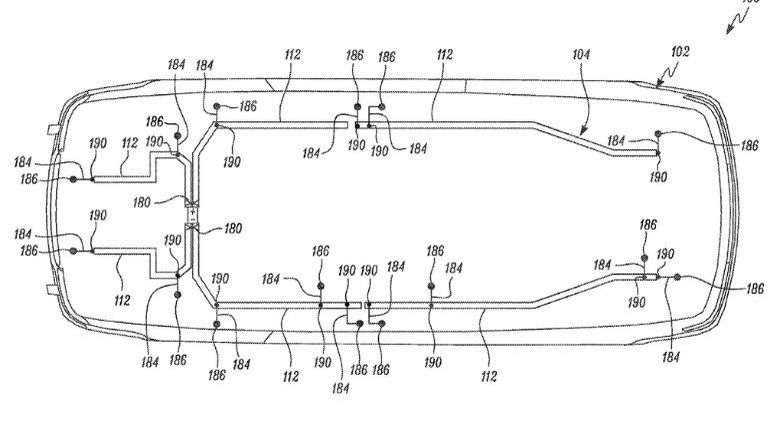

Unlike the current system, Tesla's patented modular wiring will contain the bulk of the wiring within their region of the vehicle. For example, every wire and sensor associated with the door will be neatly contained in the door assembly. Shorter wires will run from each sensor to a specific door controller, which then connects to the data bus with only two wires.

Reducing wire length has been a conversation since the reveal of the Model Y crossover. As early as 2017, Elon Musk had been reported stating that a vehicle like the 2012 Model S used just under two miles of wiring. During a quarterly earnings call, Musk had allegedly touted the 2020 Model Y as having only 300-plus feet of wiring thanks to new wiring architecture.

The new system will not only greatly reduce the amount of wiring used per vehicle, but it will also streamline manufacturing. According to the 2018 "Wiring System Architecture" patent filing, components will snap into position and fit into all associated components similarly to a building blocks model. The manual process of wiring each electrical system will be automated, which, of course, poses a concern of job security that hasn't been addressed yet. The patent was granted as of January 2022, and while Tesla hasn't confirmed which vehicles will start seeing the new modular wiring, the Cybertruck is the first of the manufacturer's line to feature the new 48v system.