The History Behind One Of Honda's Best Inventions: VTEC

Honda's Valve Timing and Lift Electronic Control (VTEC) is arguably the most well-known engine type in the world. The essence of Honda's VTEC system lies in its ingenious approach to valve control — it operates by altering the valve timing, lift, and duration, adapting to the engine's RPM and load to optimize performance. At lower RPMs, VTEC prioritizes fuel efficiency and smooth operation, utilizing a cam profile that opens and closes the valves earlier. When the engine reaches higher RPMs, VTEC activates a different cam profile, allowing the valves to open wider and longer, unleashing additional power and performance.

This real-time adjustment of valve operations enables the engine to breathe more efficiently, ensuring optimal air-fuel mixture and combustion at varying speeds and loads. The brilliance of VTEC is its ability to provide the best of both worlds: it delivers enhanced fuel efficiency at lower speeds and increased power output at higher speeds. This dual nature makes VTEC a versatile and invaluable asset in engine technology.

VTEC's innovative mechanics have had a profound impact on automotive engineering, inspiring subsequent advancements in variable valve timing technologies. Its introduction marked a paradigm shift in engine design — but how did it all come to be?

[Featured image by Nheyob via Wikimedia Commons | Cropped and scaled | CC BY-SA 4.0]

The origins of VTEC

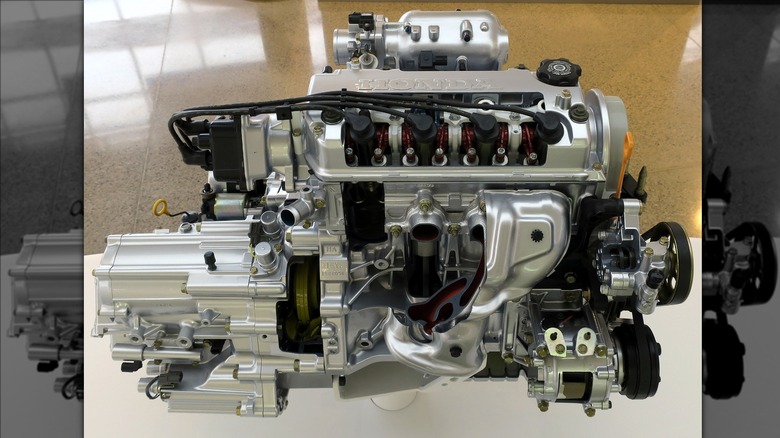

The VTEC system has roots in the early 1980s, stemming from research and development in Honda's motorcycle division. The genesis of VTEC was fueled by the aspiration to meld high-performance capabilities with optimal fuel efficiency within internal combustion engines. This was also in the aftermath of the 1979 oil crisis when Japanese engineers were pressured to develop a lower fuel consumption system. These circumstances and Honda's New Concept Engine program led to the invention of the 4-valve per cylinder double overhead cam (DOHC) that was functioning in the Honda and Acura automobiles in 1986.

In the past, four-valve-per-cylinder engines with high revs gave up low-end torque to generate higher revving horsepower. According to Honda, low-end torque suffers because of the complex interactions between the timing, lift, and duration of the intake and exhaust valves when tuned to provide high-revving horsepower. An engine's high-end horsepower would suffer if the valvetrain were reset and adjusted for low-end torque. An engineer at Honda named Ikuo Kajitani found an answer to this problem by designing a mechanism that could change both the timing and lift of the valves, preventing low-end torque from being traded for high-end power or vice versa — VTEC was the result.

[Featured image by Aero777 via Wikimedia Commons | Cropped and scaled | CC BY-SA 2.5]

Introduction to the automotive world

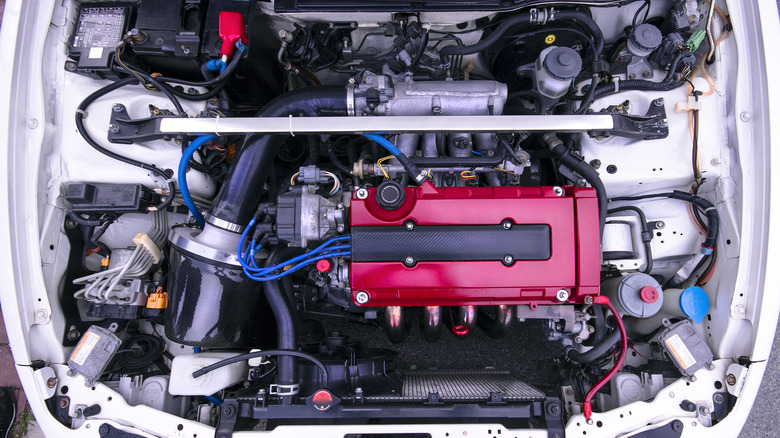

VTEC technology made its entrance into the automotive sphere with the release of the 1989 Integra XSi, symbolizing a pivotal advancement in engine technology. This inaugural implementation of VTEC demonstrated its transformative capabilities, optimizing engine performance and efficiency and highlighting its adaptability to automobile engines.

Following the introduction of the Integra XSi, VTEC quickly proliferated across Honda's automotive lineup, being incorporated into other models like the NSX, Accord, and Civic, which were modified to employ the DOHC/VTEC engine. These vehicles were equipped with the B16A engine, showcasing the versatility and impact of VTEC technology on varying car models and types. This period saw VTEC garnering acclaim and recognition, with automotive enthusiasts and experts acknowledging the balance of power and fuel economy it brought to the table.

After the SOHC/VTEC engine, which was subsequently succeeded by the VTEC-E engine in 1992, this innovation was developed into the three-stage VTEC engine, which was released in 1995 and showed an even higher level of output control efficiency.

Impact on the automotive industry

VTEC sparked a push in the automotive sector to adopt variable valve timing in engines since it was the first feasible, dependable, and commercially viable variable valve timing and lift technology. For maximum responsiveness and power, VTEC is combined with turbochargers while simultaneously assisting cars meet fuel economy criteria. The technology has not only enhanced the driving experience by providing more power and better fuel efficiency but has also contributed to environmental conservation by reducing emissions. Another notable feature of VTEC is its use in Honda bikes' undercarriage, like the Honda VFR 800, which sets this engine apart from others.

The ripple effects of VTEC's innovation have been far-reaching, inspiring a wave of research and development in variable valve timing technologies across the industry, too. Its influence is evident in the multitude of advanced valve control systems developed by competitors, aiming to replicate or surpass the benefits offered by VTEC.

Evolution and legacy of VTEC

Over the years, Honda's VTEC technology has undergone extensive refinement and evolution. Each iteration of VTEC has built upon the successes of its predecessors, introducing enhancements and innovations to meet the evolving demands of drivers and environmental standards. Early variants emphasized performance above everything else, but more recent versions focus on fuel efficiency and provide a good balance. In fact, VTEC was even called the "dream engine," given its industry-leading characteristics at the time.

The Japanese manufacturer realized they had succeeded with VTEC. They proceeded to develop it because of its popularity and most likely continue to do so. A great example is the fact that it powers the 2023 Honda Civic Type-R. The Type-R's 2L motor has increased its output to 315 horsepower thanks to the VTEC and the turbo. Because of this setup, the Civic Type-R quickly claimed the title of the fastest front-wheel drive car to lap the Nurburgring and is arguably its most formidable rival in the hot hatch category.