F-35 Engine: The Incredible Turbofan Powering The World's Most Advanced Fighter Jet

Recent discussions surrounding the armed force's latest and most tech-laden fighter jet ever, the F-35 Lightning II, had manufacturer Lockheed Martin suggesting replacing the aircraft's current engine altogether rather than executing a previously planned upgrade program. In a recent interview with Breaking Defense, Greg Ulmer, Lockheed's executive vice president of aeronautics stated, "I'm going to advocate, and I do advocate, for [the Adaptive Engine Transition Program, or AETP], another engine." Ulmer continued, "I think some of the approaches today are very short-sighted and not considering a longer-term view."

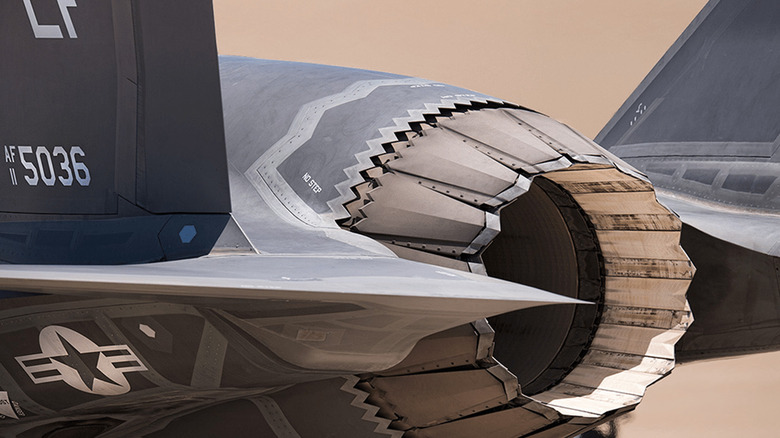

Since the F-35 is expected to fly until the year 2070, its handlers can't be faulted for looking toward the future, but the fact is that the jet's current Pratt & Whitney F135 turbofan engine is pretty darn amazing in its own right and due to budget constraints, will continue to power the F-35 for the foreseeable future.

The F135's history begins with a strong pedigree since it evolved from the F119 turbofan that powers the F-22 Raptor fighter jet. First seen in the late 1990s, the F119 has a reputation as the safest fighter engine in U.S. Air Force history. Since the F-35 is powered by a single engine only, it has to be a robust one. Indeed, the F135 is rated at 43,000 pounds of thrust while utilizing its afterburner, which is more than the two engines powering a "Top Gun" movie-era F-14 jet combined.

It can also fly vertically

There are actually three different variants of the F135: One for conventional takeoffs and landings, one specialized for use on aircraft carriers, and a short take-off and vertical landing (STOVL) version. The conventional and aircraft carrier versions are largely similar, except that the carrier engine has superior corrosion resistance to stand up to the saltwater environment of shipboard life. The STOVL engine, however, is a completely different animal. Developed in collaboration with Rolls-Royce, this engine features a 3 Bearing Swivel Module that acts as a thrust vectoring nozzle that, coupled with a lift fan in the front of the aircraft, facilitates vertical lift-off just like Harrier AV-8B Jump Jets of old.

Besides performance, reliability was also a key initiative in F135 development. To that end, fewer parts were used compared to similar engines and it's been said that all field-replaceable parts and maintenance can be negotiated with six common tools available at any hardware store. Also present onboard is a Health Management System that transmits real-time data to maintenance personnel on the ground, who can prepare for and ready any necessary parts before the aircraft even lands, reducing downtime.

For the time being, a repower for the stealthy jet has been shelved, but the F135 is undergoing an Engine Core Upgrade that will involve thermal management to address a well-known overheating conundrum, as well as increased capacity to generate additional electricity that's required for the overall jet's Block 4 upgrade that's now underway.