This Newly Discovered Method To Recycle Lithium Batteries Could Be A Gamechanger For Electric Cars

The number of electric passenger vehicles sold globally surpassed 10 million vehicles last year alone, so it's safe to say that the era of the electric vehicle is upon us. A primary driver of this trend is a societal shift away from fossil fuels in favor of renewables. But as the popularity of electric vehicles has increased, so has the need to mine lithium for the production of rechargeable lithium-ion batteries, which comes with its own environmental challenges.

Scientists have tried addressing the issue by researching more efficient batteries like solid-state lithium-metal batteries or batteries that instead rely on oxygen. In Germany, India, and elsewhere, authorities have been searching for — and finding, with varying degrees of success — previously untapped sources of lithium, but this feels little removed from the problems associated with digging up coal.

And now, as the first wave of electric vehicles begins to cycle out of use, a new hurdle has emerged: what to do with all those spent batteries. Of course, passenger vehicles are hardly the only products that rely on lithium-ion batteries — think everything from cell phones and home solar power storage to power tools, vaping devices, and electric toothbrushes — but in terms of pure tonnage they're the drivers of a seismic shift in our thinking about what it means to be sustainable. Luckily, scientists have a new method for putting these old batteries back to work.

Round and round we go

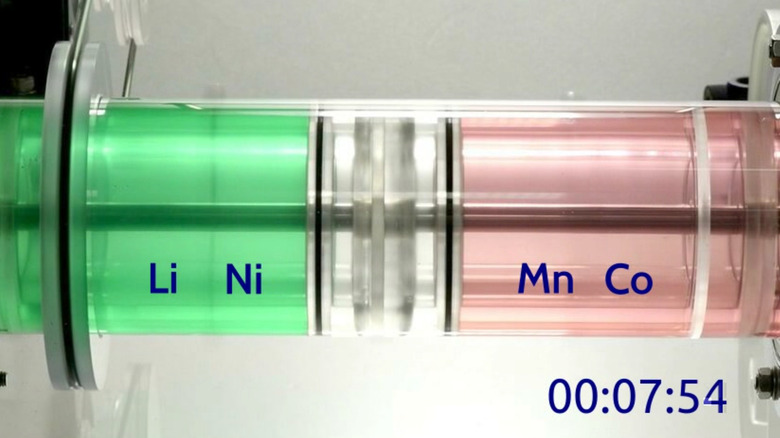

According to a paper recently published in the scientific journal Advanced Materials, a team of scientists has discovered a new and somewhat unique method of recovering the raw materials from used lithium-ion batteries. The technique uses a rotating reactor that's segmented into three liquid-filled sections. On one end is the "feed" solution, and the other end holds the "acceptor" solution. The two are separated by an extractant called the "shuttle."

At the end of a lithium-ion battery's useful life, some of its chemical components are mixed together, which is a major challenge when it comes to reusing the materials. With this new method, the mixed materials can be injected into the feed solution while the reactor is rotating. The elements move back and forth from one end of the reactor to the other, passing through the shuttle in a process that's something akin to passing through a sieve. As the reactor rotates, the elements separate to different sides, making them much easier to collect and reuse. Amazingly, the process takes only a matter of minutes while also using a lesser amount of chemicals compared to related methods.

This is a huge milestone for the viability of large, mass-produced lithium-ion batteries. Of course, other practical obstacles remain, such as building a battery recycling industry infrastructure that doesn't involve constantly shipping spent batteries halfway around the globe, but still, this is a big deal. Then again, by the time we get lithium-ion recycling figured out maybe we'll already be switching to hydrogen.