The Tesla Next-Gen Car Is All About Efficiency And Control

No actual cars were unveiled during the Tesla Investor Day 2023 event, which was held at the company's Austin, Texas-based Gigafactory — but we were given a pretty solid indication of the direction Tesla is heading in. Future generations of the company's vehicles, along with its other products, will be more efficient, more environmentally friendly, and potentially cheaper as both the manufacturing processes and the tech that goes into the cars gets more refined.

While each Tesla EV's construction may have less of an environmental impact, the number of Tesla vehicles and other products being built is also set to increase dramatically due to the processes being implemented. Central to Musk's plans is a brand new Gigafactory, which is set to be built in Monterrey, Mexico. Musk insisted that the new factory isn't shifting jobs from any of Tesla's current production centers. Instead, it is part of a plan to "expand" the company's "global output." Part of that expansion is the creation of the next generation of vehicles, which are designed to be a "huge volume product."

Tesla's next-gen is to be greener, cheaper, and more efficient

Efficiency seems to be at the core of Tesla's next-generation vehicle platform. The cars themselves will be easier to assemble and can be assembled more quickly, thus increasing the company's output. The vehicles' powertrains won't be manufactured with rare-earth metals, as well, reducing costs and drastically reducing the Tesla vehicle's environmental impact.

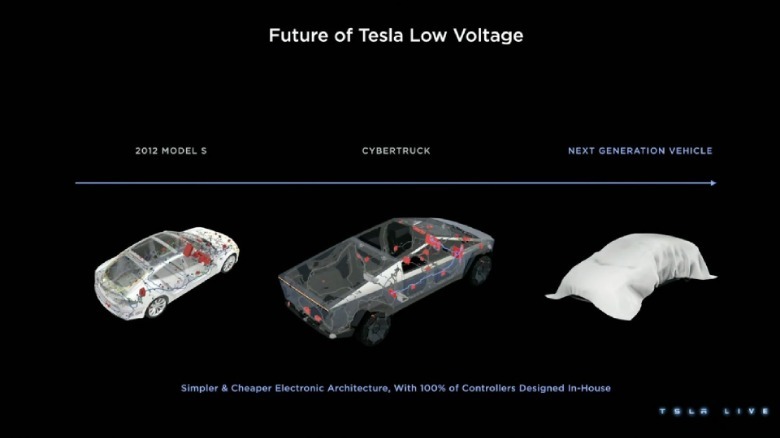

To put things in perspective, the company's next drive unit will contain 75% less silicon carbide, cost around $1,000 to produce, and have half the carbon footprint of current drive units. All in all, advancements in technology and efficiency could mean the cost of producing a next-gen Tesla is around 50% that of a Model Y. The cars themselves will also be more efficient. Tesla's new 48-volt architecture uses far less energy than the current offerings and is also lighter. The reduction in cost and increased output could make electric vehicles more viable for a wider range of people.

The company, which has always put an emphasis on its own designs, is also planning on building even more parts in-house. In the future, the controllers used in the automaker's products will all be designed and produced by Tesla. These controllers will be spaced throughout next-gen vehicles and connected via Ethernet to form what Tesla terms a "consolidated vehicle network." Production of the vehicles is expected to take place over the next few years — though this is Tesla, and it has never been averse to pushing deadlines back when needed.