Why Doesn't Your iPhone Have Sapphire Glass? It's Really Hard (To Make)

It's a lesson many companies learn, though not many as publicly as GT Advanced. The now-defunct Sapphire glass supplier to Apple went belly-up recently, taking hopes of a Sapphire glass-laden iPhone with them. Apple's idea was to have Sapphire glass production scale to meet their admittedly high demands. GT was willing to meet the challenge, but a new report suggests the entire partnership was doomed from the start. Given the evidence found, hindsight might make you feel silly you ever thought your iPhone 6 would have Sapphire beyond Touch ID.

Sapphire is created in a boule, which is like a chunk of clear material (with regard to Sapphire glass, at least). The boules are about 600 pounds, take 30 days to produce, and cost nearly $20,000. According to people familiar with the goings-on with GT and Apple, over half of those boules were unusable.

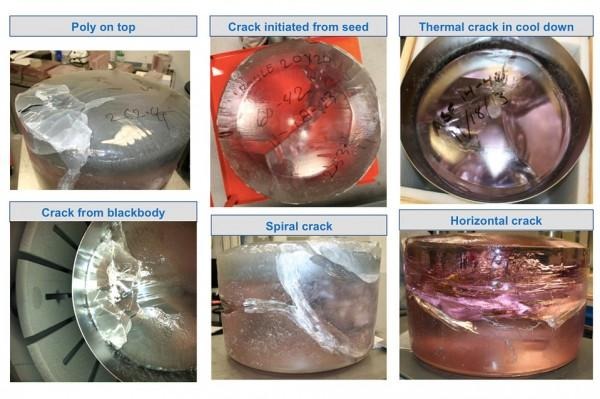

To the scale Apple wanted Sapphire, it just wasn't going to work. Leading into the partnership, none of the boules GT produced were any good. All had terrible flaws. In an attempt to salvage the operation, the decision was made to produce 363-pound cylinders rather than chunks twice as big. When a cylinder was good enough for use, GT would cut them into smaller pieces, bricks roughly the size of an iPhone 6 or 6 Plus display.

Still, the operation spiraled out of control. the deal with Apple would bring GT a solid source of revenue, but they were hemorrhaging cash to fast to ever make it up. They spent nearly $1 billion to get the factory up to speed — ahead of even making a dime from Apple. That massive spend was also double what their loan from Apple was.

GT said Sapphire quality would improve, but it never did. Touch ID might be possible, but GT was far from capable of producing Sapphire for displays. The rest, well, it's in the timeline below.

Source: The Wall Street Journal