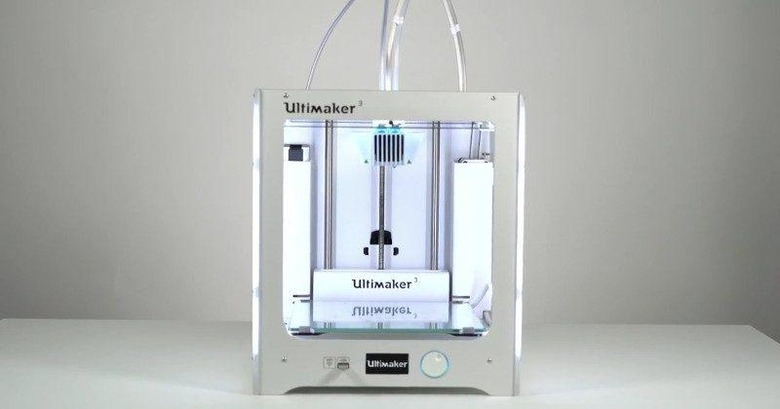

Ultimaker 3 Printer Lets You Create More Complex Shapes

3D printing started out as a movement that democratized the production process away from big businesses and into small groups and even individuals. Naturally, over time, the benefits and savings of 3D printing found its way back to groups and businesses that can afford to throw more cash at a problem. Ultimaker is one of the biggest names in the 3D printing industry catering to professionals. And after more than three years, it is launching its next gen flagship box, the Ultimaker 3D.

As magical as 3D printing might seem, it is ultimately limited by the materials it can use to print with and the shapes it can create. All 3D printers started out with solid, simple objects but today's 3D printers, like the new Ultimaker 3, can already generate more intricate geometries, with lots of gaps in between and, sometimes, even moving parts.

The trick to this is a combination of dual extrusion and water-soluble material. In a nutshell, the Ultimaker 3 actually prints two things using two different materials. One is actual geometric product desired, printed with something like Nylon. The other is the structure that will support said geometric shape, printed in water-soluble material like PVA. Both materials are supported by the Ultimaker 3. Once the printing is done, simply leave the object underwater and watch the excess structure melt away.

The Ultimaker 3 improves on the capabilities of its predecessor while retaining the parts that work. Most popular among those is the built-in camera and open source CURA software that allows owners and organizations to keep a remote eye on the printing process.

As a 3D printer that's being marketed to professionals, the Ultimaker 3 naturally carries a "professional" price tag. Available today, the Ultimater 3 goes for $3,495