This CAL 3D Printer Uses Photosensitive Liquid And Beams Of Light

There's a new sort of 3D printer in town, and it goes by the name CAL. This printer was created by a team at UC Berkeley, and its potential is vast. The most popular method for consumer-level 3D printing right this minute is layer-by-layer – through the melting of a material that's been spun into a line. The new method we're looking at today is similar, but makes objects form from a completely different angle.

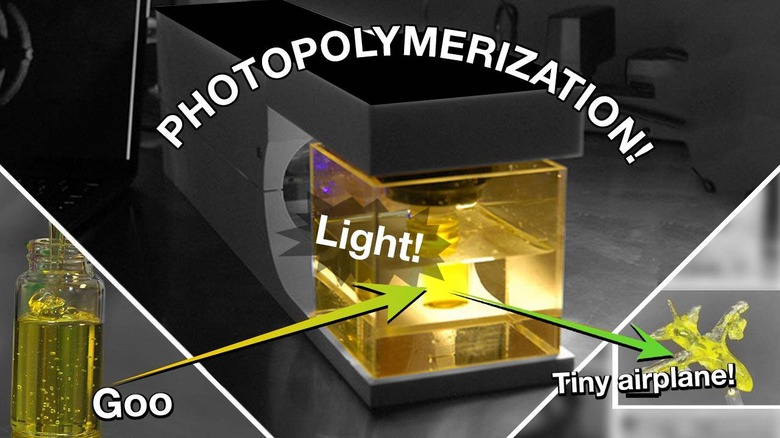

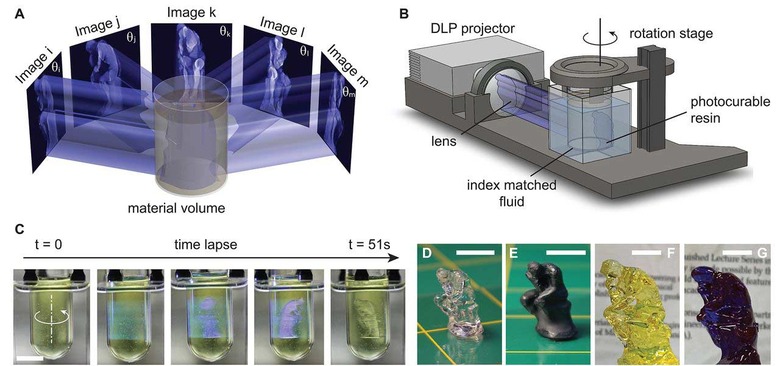

The system we're looking at today goes by the name Computed Axial Lithography (CAL). Photopolymerization is used to create objects volumetrically. A photopolymer is a material (a polymer) which changes when exposed to light – in this case, the polymer becomes solid when exposed to the appropriate amount of light. With CAL, photopolymerization shoots a beam of light into a big cup of this special liquid, and a hard object is made.

It's easier to visualize if you actually see it in motion. Below you'll see a video with a CAL machine in motion. This new sort of printer is not ready to roll for consumer use, nor even really for any public sort of use. But it's real, and it's really in working order right this minute.

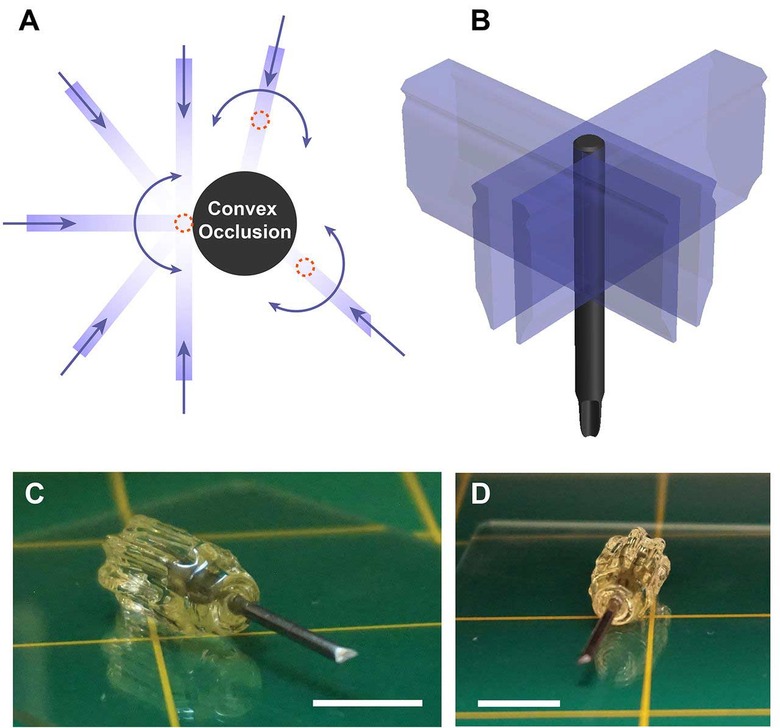

This sort of printer could overcome most of the limitations of current common printing methods. One of the ways in which this system overcomes limitations of previously used methods is in the printing around preexisting solid objects. Imagine having a tool which requires a new handle – with this CAL system, the handle could be printed directly on to the tool.

The research on this method suggests that this method "may be used to circumvent support structures as it can print into high viscosity fluids or even solids." CAL, they say, is scalable to larger print volumes, and is several orders of magnitude faster, under a wider range of conditions, than layer-by-layer methods.

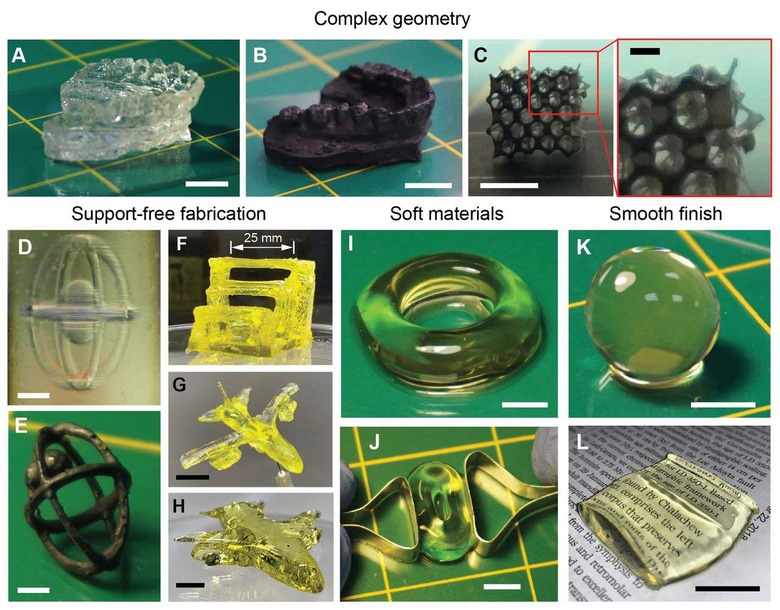

Above you'll see a collection of different objects printed with CAL. Extreme levels of complexity, fabrication of complex objects without the need for fabricated supports, soft materials, and extremely smooth finishes. Now, if only I could get one in my basement so I can start printing a tiny army of alien action figures, we'd be set!

Also note – we've spoken of this sort of printing before – in patent form. Have a peek at our article from this January, 2019 to see this printing technique print out the letter M!

For more information on this subject, head over to Science magazine where the paper "Volumetric additive manufacturing via tomographic reconstruction" can be found. The code DOI: 10.1126/science.aau7114 marks the spot, the place where the paper is authored by Brett E. Kelly, Indrasen Bhattacharya, Hossein Heidari, Maxim Shusteff, Christopher M. Spadaccini, and Hayden K. Taylor.