Rocket Lab Neutron Launch Vehicle Revealed With 'Hungry Hippo' Tech

Putting satellites, cargo, and astronauts into space is an expensive proposition. As a result, all the private companies working with NASA are attempting to reuse some of the rocket hardware to help reduce the cost of launches. SpaceX is the best-known company in the private space industry, with its Falcon 9 rockets being routinely reused. While SpaceX may be the best known, it's certainly not the only private company working to put satellites and other cargo into orbit as efficiently and cheaply as possible.

One of those companies is Rocket Lab, and it recently shared details on its Neutron launch vehicle's advanced architecture. The company shared details on the Neutron vehicle via a virtual event streamed via YouTube earlier this month. The Neutron launch vehicle builds on the company's experience utilizing its Electron launch vehicle.

Rocket Lab points out that its Electron launch vehicle is the second most frequently launched rocket in the US annually since 2019. The Neutron launch vehicle is an eight-ton payload class rocket designed to provide cost-effective and reliable launch services for satellite mega-constellations, human spaceflight, and deep space missions. Rocket Lab founder and CEO Peter Beck says Neutron isn't a conventional rocket.

Back says Neutron is a "new breed" of launch vehicle with improved reliability, reusability, and cost reduction as part of its design from the beginning. Beck went on to say more than 80 percent of satellites that will be launched in the next ten years will be part of constellations. A constellation of satellites could have thousands of individual satellites designed to provide complete coverage of the entire world. One of the biggest constellations of satellites in orbit today is the SpaceX Starlink constellation designed to provide broadband to the entire planet.

Rocket Lab says that the Neutron rocket is sized for market demand and to be able to launch quickly, affordably, and frequently. One of the more interesting aspects of the rocket's design is that it will be the world's first carbon composite large launch vehicle. The Electron rocket was the first orbital rocket to use carbon composite and has operated frequently and reliably to place small satellites into orbit since 2018.

For Neutron, Rocket Lab uses a new specially formulated carbon composite material designed to be lightweight, strong, and survive immense heat and other forces related to launch and reentry. The carbon composite structure of the rocket is built using an automated fiber placement system capable of building meters of carbon rocket shell in minutes.

One thing that private space companies agree on is that reusability is key to affordable launches. The ability to launch, land, and launch again was baked into all aspects of the Neutron design from the beginning. The rocket has a shape that features a tapered rocket paired with a wide base providing a stable base for landing, so the rocket doesn't need legs complicated mechanisms supporting landing.

An interesting aspect of the rocket's design is that the structure is balanced enough that it doesn't need bulky launch site infrastructure like launch towers. Neutron can stand on its own for liftoff, and once in space, the second stage will deploy while the first stage returns to Earth to land the launch site. Rocket Lab says its launch and recovery method eliminates the need for any landing platforms in the ocean. That is a jab directly at SpaceX, which typically recovers its first stage rockets using autonomous drone ships in the ocean.

Rocket Lab also offered some details on the Archimedes rocket engine designed and manufactured in-house. Archimedes is a reusable liquid oxygen/methane gas generator cycle engine that can generate 1 meganewton of thrust and 320 seconds of ISP. Neutron's first stage will use seven Archimedes engines, with the second stage powered by a single vacuum optimized Archimedes engine.

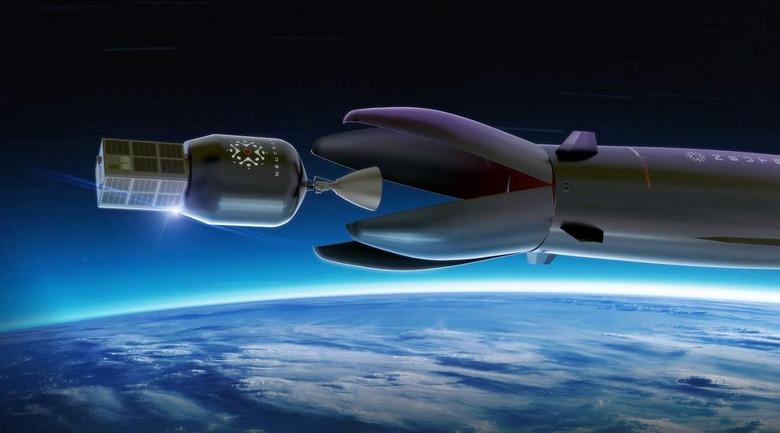

Another interesting design choice Rocket Lab made was designing the fairing dubbed the "Hungry Hippo" design. The design eliminates the need to replace the fairing for each mission. By comparison, SpaceX tries to capture its fairings and reuse them, but it's not always successful. The Hungry Hippo fairing design has jaws that open wide to release the second stage and payload.

The fairing then closes again for the first stage to return to Earth. Rocket Lab says its design will increase launch frequency and eliminate expensive and unreliable methods of capturing fairings at sea. Since the second stage is completely enclosed within a fairing, the stage was designed to be the lightest second stage in history. The second stage is part of the launch vehicle exterior and structure with most rockets.

By designing the rocket to house the second stage completely inside the fairing, it doesn't need the same strength required of second stages exposed to harsh environments at liftoff. This allows the second stage to be much lighter, providing higher performance once in space. Currently, the second stage is expendable. It measures six meters long and is made from a carbon composite structure powered by a single vacuum optimized Archimedes engine.

Rocket Lab is currently going through a competitive process to choose a launch site, rocket production facility, and Archimedes engine test facility somewhere on the East Coast of the United States. The company will create 250 jobs to support the Neutron program.