Robotic Extrusion Does 3D Printing With A Robot Arm

A pair of researchers are working on a new robotic 3D printing system that has been dubbed Robotic Extrusion. The process uses a 6-axis robotic arm that is able to print items thanks to a print head attached to the arm. The goal of the project is to eliminate the line between designing and fabricating. For instance, the system could be used by architects to provide something other than flat drawings and construction notes to teams of builders.

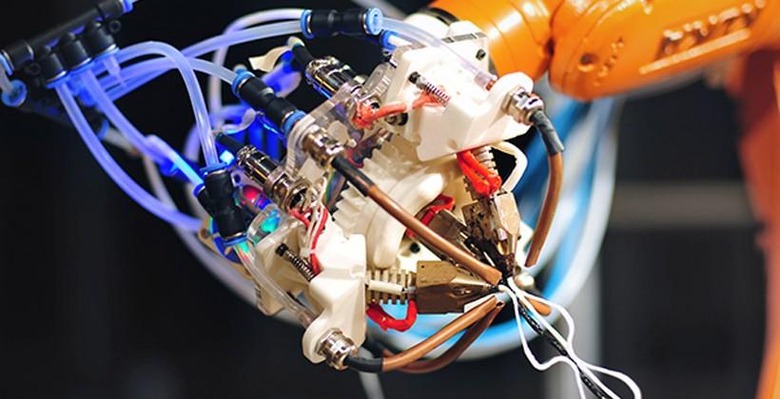

The robotic arm is made by KUKA robotics and has six axis of control. The printing process involves the superimposition of thermoplastic ABS/PLA material along the direction of gravity. The print head mimics the structure of spider silk thread.

By mimicking spider silk, the print system is able to print self-supporting forms and grow the form from the ground up. What makes the print system able to produce biomimetic structures is a delicate robotic-end effector. The main component of this device is a petaloid turn-plate that has three movable printing heads positioned around a fixed print head in the center.

The entire system is servo controlled and rotation of the turn-plate enables an oscillating motion of the print head's three movable elements. The robotic motion of the arm is controlled using Arduino and each of the heaters inside the head that melts the filament is individually programmable. The print material is delivered using four individual servos. The speed of filament delivery and head rotation can be changed via the switches.

SOURCE: Behance