Researchers Create A 3D-Printed Bioresorbable Airway Stent

Researchers from ETH Zürich created a new 3D-printed airway stent that is bioresorbable. Researchers believe the new stent could simplify the future treatment of upper airway obstruction. The new device is usable for treating narrowing of the trachea or the main bronchi due to injury or illness.

This type of injury or illness can lead to death because it can restrict the amount of oxygen the person gets to the brain. Today, surgeons use stents made of silicone or metal as a way to treat those patients. However, metal stents have to be removed surgically when they're no longer needed leading to the potential for infections and surgical difficulties.

Silicone stents can migrate away from the insertion site. Researchers say that is because the implants aren't adapted to the patient's anatomy. The new stent developed by the researchers is tailored specifically to the patient and is bioresorbable. Being bioresorbable is important because it allows the stent to gradually dissolve after it's implanted.

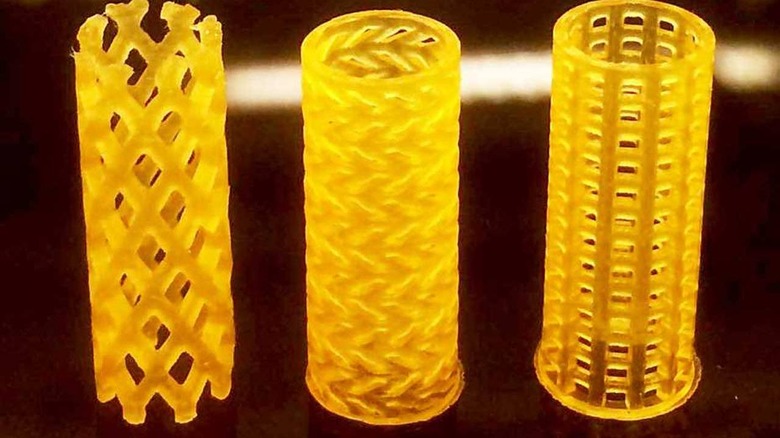

The 3D printing process used to create the stent is known as digital light processing and uses light-sensitive resins that have been adapted specifically to this purpose. The process requires researchers to create a computer tomography image of a specific section of the airway. That image is used to develop the 3D model for the stent before transferring the data to the DLP printer.

The UV light shined from the printer hardens a resin building the stent layer by layer. The newly developed resin is too thick at room temperature requiring it to be processed at temperatures of 70 to 90 degrees Celsius. Inserting the stent does require a special instrument because they have to be folded. The implants can't be kinked or squeezed in the wrong direction and do have to unfold precisely at the target location.