MIT Researchers Improve Perovskite-Based Solar Panel Efficiency

Today, solar panels are typically made of silicon, but in the future, they could be manufactured from a different material that offers more efficiency and lower manufacturing cost. The material that could replace silicon for these next-generation solar panels is called perovskites. MIT researchers say that perovskites offer the potential for low-cost, low-temperature manufacturing of extremely thin and lightweight, flexible cells.

However, currently, the efficiency of perovskite-based solar panels for converting sunlight to electricity is less than that of silicon-based panels and that of other alternative materials. MIT has developed a new approach to designing solar panels using perovskite that has resulted in panels that match or exceed the efficiency of today's typical silicon cell.

The efficiency of a typical silicon-based solar panel today is somewhere in the 20 to 22 percent area. The researchers used a specially treated conductive layer of tin dioxide bonded to the perovskite material to provide an improved path for the charge carriers in the cell. The perovskite formula was also modified and combined with the new conductive layer allowing researchers to boost the overall efficiency of the solar cell to 25.2 percent.

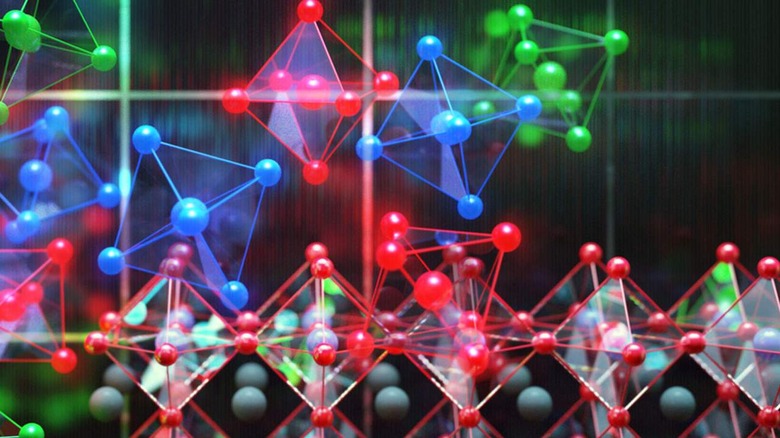

Researchers say that is close to a record for such materials and better than the efficiency of many existing solar panels. One downside to perovskite's for solar panels is that they still lag significantly in longevity compared to silicon-based panels. Perovskites are a broad class of materials defined by having a particular molecular arrangement or lattice resembling that of the naturally occurring mineral perovskite.

Scientists note that there is a wide range of possible chemical combinations that can make perovskites. The class of materials is widely appealing to researchers because it appears that they could be made more cheaply than silicon or gallium arsenide. One downside to gallium arsenide, which is another alternative material for solar panels, is that it requires heat of over 1000 degrees Celsius for manufacturing.