MIT Researchers Create An Improved Nasal Swab For COVID Testing

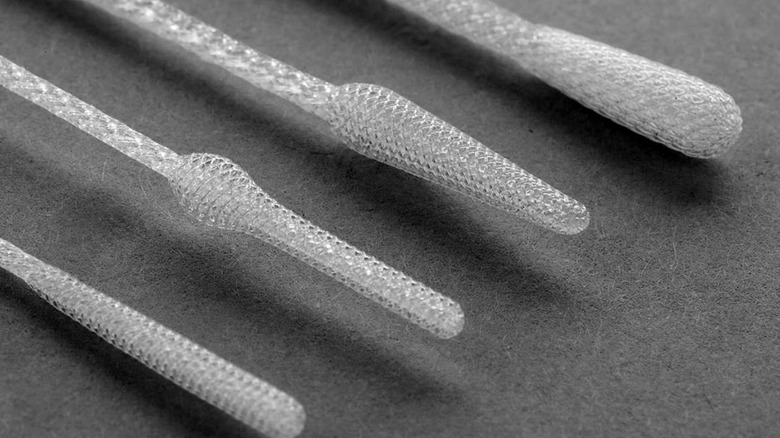

MIT researcher Jifei Ou operates a company called OPT Industries. The company has been working with hospitals to deliver a new type of nasal swab for COVID-19 testing. The swabs were created using 3D printing systems utilizing thin, hair-like structures Ou developed while at MIT. The swabs have tiny woven lattices that can absorb and release more fluid than conventional swabs.

OPT Industries is a spinoff from MIT utilizing a continuous manufacturing approach allowing it to scale printer production with demand. The company has supplied over 800,000 swabs so far to a number of healthcare and at-home testing organizations. Its production has helped overcome shortages that were threatening the ability of testing organizations to operate.

OPT has multiplied its manufacturing and distribution capabilities in the years since it began helping with COVID-19 testing products and has partnered with large healthcare organizations, including Kaiser Permanente. The company is also developing other products that could benefit from the design processes it uses.

While at MIT, Ou created new ways to design and 3D print intricate microstructures. The work his team was involved with required it to build its own 3D printer, create design software, and develop special polymers to meet durability and resolution requirements. Ou received support from MIT Sandbox and the E14 Fund for his company and also credits the MIT Industrial Liaison Program to help him secure industry connections.

Since leaving MIT, the researcher has improved the throughput of his 3D printing machines to enable continuous printing and allowing the company to focus on creating flexible, textile-like materials. The swabs created by OPT can hold 20 times the amount of bacteria for testing, which is critical because more specimens increase the sensitivity of tests.