MIT Develops A New Method To Control Ferrimagnets

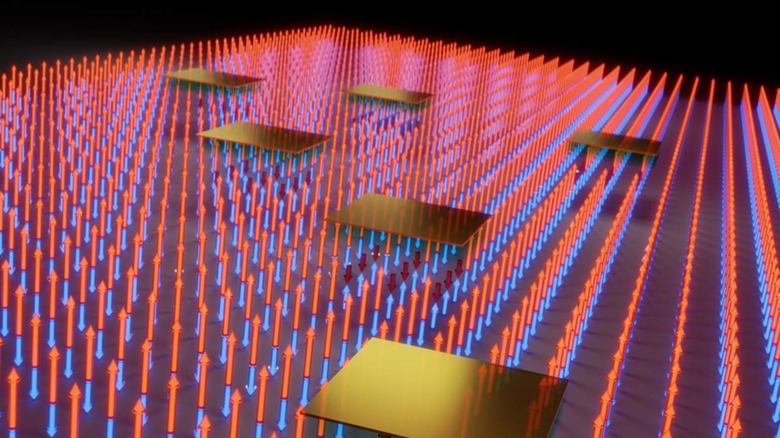

Researchers at MIT have developed a new way to control magnets made of ferrimagnetic materials. Unlike ferromagnetic materials, in a ferrimagnetic material, some of the atoms are aligned in one direction, with others aligned the opposite way. Therefore, what type of magnetic field is produced by a ferrimagnetic material depends on the balance between the two types of atoms.MIT researchers believe that since the magnetic properties of ferrimagnetic materials are strongly influenced by external forces, they should be usable to produce faster data storage and logic circuits. Storage based on this type of material would allow more data to be packed in a given space than ferromagnets. MIT researchers have worked with scientists from other institutions to overcome a limitation of using ferrimagnetic materials in data storage.

That challenge was that there had been no reliable way of switching the orientation of the magnets to generate the 0s and 1s needed for data storage. The researchers discovered a method of rapidly switching the magnetic polarity of a ferrimagnet 180 degrees via a slight voltage change. Researchers believe their discovery could result in a new era of ferrimagnetic logic and data storage devices.

The system uses a gadolinium cobalt film, which is a material that falls into a class called rare earth transition metal ferrimagnets. In this type of material, the gadolinium atoms have a magnetic axis aligned in one direction while the cobalt atoms are aligned in the other. When applying a voltage to enable the splitting of water molecules on the film's surface into oxygen and hydrogen, the oxygen is vented away, while the hydrogen atom nuclei can penetrate the material.

That penetration alters magnetic orientation and the changes enough to switch the net magnetic field orientation enabling data storage and magnetic memory devices. The process the team devised is also highly energy-efficient because it needs only a change in voltage and no applied electrical current that could lead to heating. In experiments, the team subjected their material to 10,000 polarity reversals with no signs of degradation.