MIT Creates 3D Printed Soft Brain Implants

Scientists MIT have created a new type of brain implant that is much better than the traditional rigid brain implant commonly used today. The scientists say that brain implants made from metal or other rigid materials can, over time, cause inflammation and the buildup of scar tissue inside the brain. The implants that the MIT researchers have created are 3D printed soft, rubbery implants.

Soft, flexible neural implants can conform to the contours of the brain and can monitor activity over more extended periods without aggravating any surrounding tissue. The flexible electronics could offer alternatives to metal-based electrodes designed to monitor brain activity. Flexible electrodes could be used in brain implants that stimulate neural regions to ease the symptoms of conditions such as epilepsy, depression, or Parkinson's disease.

MIT's implants are made from an electrically conductive polymer. The polymer chosen is typically liquid-like, but they were able to turn it into a more viscous toothpaste-like substance that could be fed through a conventional 3D printer. By using the 3D printer, the team can make stable and electrically conductive patterns.

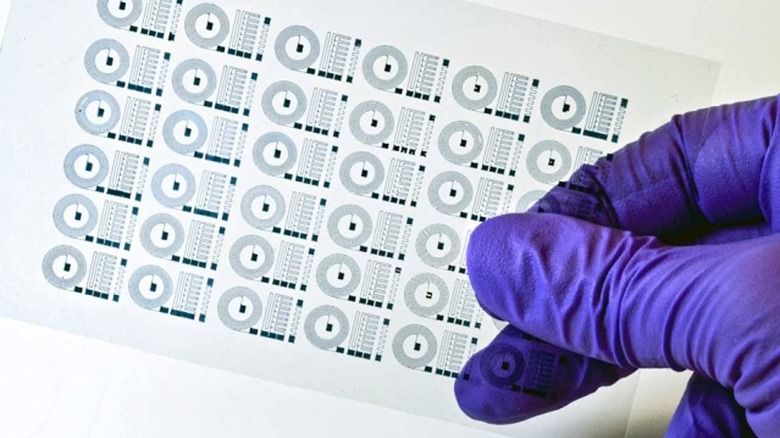

The team was able to print multiple soft electronic devices, including a small and rubbery electrode that was implanted into the brain of a mouse. As that mouse moved around, the team was able to observe activity from a single neuron. One significant benefit of using a 3D printer to create these flexible electrodes is that the design can be changed, and a completely new version of the sensor can be available in about 30 minutes.

In their study, the team modified poly polystyrene sulfonate, which is a conducting polymer typically supplied in the form of an inky, dark-blue liquid. The mixture is a combination of water and nanofibers, with the latter providing electrical conductivity. To thicken the mixture, the team used a solution of water and organic solvent to form a hydrogel. They found that a range between five and eight percent by weight of nanofibers produced a toothpaste-like material that was electrically conductive and suitable for feeding into a 3D printer.