Microsoft Cools Data Center Servers Using Boiling Liquid

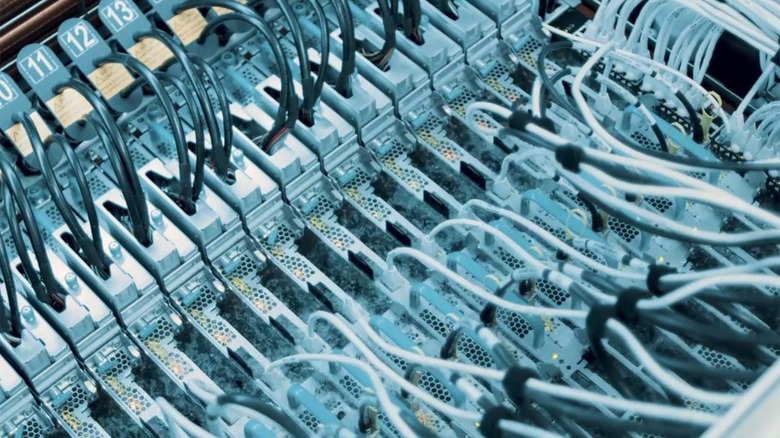

One of the biggest challenges in running a massive data center is keeping the computer hardware cool. Over the years, Microsoft has tried some interesting solutions when it comes to cooling, including sinking some servers in the ocean inside sealed containers. Microsoft is now using boiling liquid to cool data center servers at a data center on the eastern bank of the Columbia River.

The boiling liquid that Microsoft is using isn't water. It's a fluid that's harmless to electronic equipment and engineered to boil at 122 degrees Fahrenheit. That's 90 degrees lower than the boiling point of water. The fluid is placed inside a couch-shaped tank, and the servers generate the heat required to make the fluid boil as they carry out normal operations.

The boiling effect carries away heat from the computer processors and other components, allowing me servers to operate continuously at full power without risking failure due to overheating. Vapor rises from the boiling fluid and comes in contact with a cooled condenser in the lid of the tank. That causes the vapor to change the liquid and rain back onto the immersed servers to create a closed-loop system.

Microsoft says that it's the first cloud provider running two-phase immersion cooling in a production environment. Microsoft says production environment deployment for two-phase immersion cooling is the next step in its long-term plan to keep up with the demand for faster and more powerful data center computers. It's become a challenge to make reliable advances in computer chip technology using traditional air cooling.

Microsoft notes that for decades Moore's law saw chips advanced by packing more transistors onto the same size chip resulting in roughly double the speed for computer processors every two years without increases in power demand. However, increasing speeds have begun to slow because transistor widths have shrunk to the atomic scale and are reaching a physical limit. To keep improving performance, the industry has turned to chip architectures able to handle more power which in turn increases the heat output.