Micro-Windmills Could Charge Your iPhone With Waving

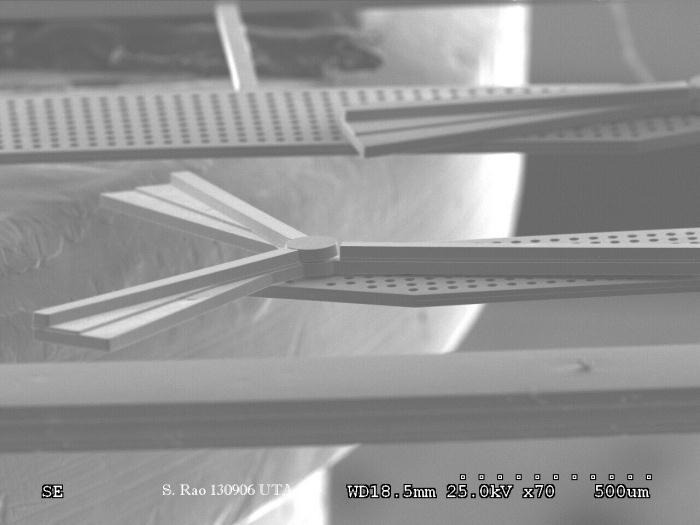

Forget angels dancing on the head of a pin, recharging tomorrow's mobile devices could be a question of how many micro-windmills can you fit on a cellphone cover, with one team of researchers looking to harness the wind on a tiny scale to keep your iPhone topped up. Smitha Rao and J.-C. Chiao of UT Arlington developed the 1.8mm-wide windmills as a way of working around limits on traditional wind power generation, like size and safety. Instead of one big turbine, the pair envisage devices covered with hundreds of tiny versions.

In fact, ten of the duo's design for a new micro-windmill could fit onto a grain of rice, meaning the average smartphone case could easily accommodate many more. In theory, simply leaving your phone on a windowsill, or waving it around in the air, would be enough to generate electricity.

The duo partnered with WinMEMS to produce samples of the micro-windmills, gears, inductors, pop-up switches, and grippers, and the Taiwanese company will look at how it can commercialize the system. The 'mills themselves are made from nickel alloy, punched out of a single wafer from which hundreds or thousands can be produced.

The result is cheap production costs, calling on a strange mixture of origami concepts and planar muiltilayer electroplating; together, it means 3D objects can be self-assembled from 2D metal pieces.

According to Rao, the possibilities for the micro-windmills don't stop at portable electronics: just because they're tiny, it doesn't mean they only have tiny applications. The micro-robotics researcher predicts easily-installable windmill panels that could be fitted to the outside of homes and businesses, similar to how solar panels are installed today, and used to generate power.

That could be used as a supplement to the regular electricity grid, or alternatively to keep new sensor systems and smart home-style technology running, Rao concludes. Meanwhile, other components built using the same 2D wafer printing technology could find applications in surgical equipment, tiny sensors, and even production lines for other micro-machinery.

VIA TIME