Harvard Researchers Invent Printing Process That Uses Sound Waves

Researchers at Harvard University have announced the development of a new printing method that could have a significant impact on the manufacturing of biopharmaceuticals, cosmetics, and food. The process uses a printing method powered by sound waves to generate drops of liquid. The team says the method has an unprecedented range of composition and viscosity.

Liquid droplets are already used in a wide range of applications for printing including inkjet printing many use at home or in the office. Scientists say that the limit of Inkjet printing tech right now is that it is only suitable for liquids that are about ten times as viscous as water. The catch comes in using similar printing techniques for biopharmaceuticals and bioprinting. The biopolymer and cell-laden solutions used in those scenarios are about 100 times more viscous than water.

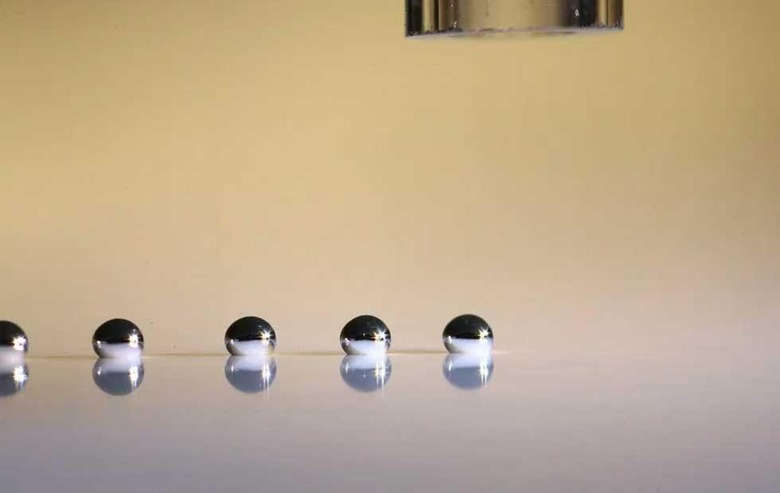

Some biopolymers like honey are 25,000 times more viscous than water. The new technique takes fluid viscosity out of the picture when printing. It uses sound waves to assist gravity in forming droplets, the technique is called acoustophoretic printing. Soundwaves are a controllable force and can pull each droplet off a nozzle when it reaches a specific size and then eject the drop towards the printing target.

Scientists say the higher the amplitude of the sound waves, the smaller the droplet and the droplet size is independent of the viscosity of the material used. During the research, the process was tested on a range of materials from honey to stem-cell ink, biopolymers, optical resins, and liquid metals with success.

The team also notes that this method is safe for materials with living cells or proteins because the sound waves don't travel through the biological cargo. The team says that the application space is limitless for the new technology.

SOURCE: Harvard University