Engineers Create Pneumatic Computer Memory To Control Soft Robots

Engineers from the University of California Riverside have revealed a new creation that is designed to control the movements of soft robots. The engineers revealed an air-powered computer memory system that overcomes one of the biggest obstacles to advancing soft robotics. That major obstacle is the mismatch between pneumatics and electronics.

Typically the movements of soft robots are controlled via air that moves into and out of bladders inside the robot. The limbs of the soft robots are flexible and rubbery, often with grippers, and soft robots can be superior to traditional rigid robots performing certain tasks, particularly those that are delicate. Soft robots are also safer for working with humans, making them a major focus of investigation by researchers worldwide. Existing systems for controlling pneumatic soft robots use electronic valves and computers to control the position of moving parts.

The electronic parts add considerably to the cost, size, and power demands of soft robots limiting their usefulness. The researchers created a system that utilizes "pneumatic logic." The theory of pneumatic logic predates electronic computers and was once used to provide an advanced level of control in components for climate control systems and other tasks in the early 1900s. In pneumatic logic systems, air rather than electricity flows to the computer channels and represents on or off.

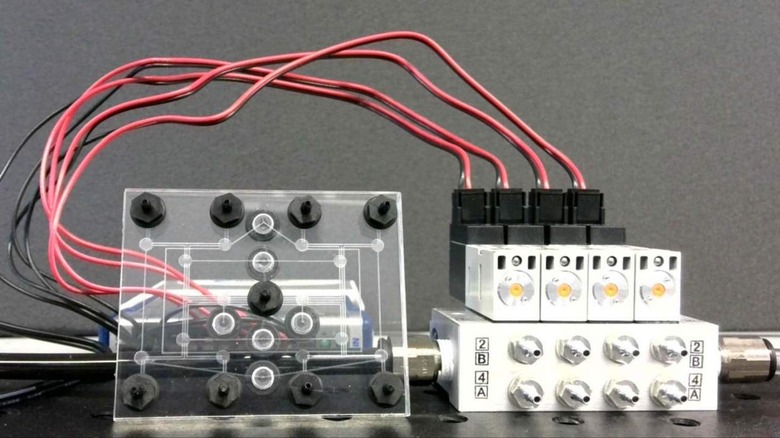

The team realized they could create pneumatic logic memory for soft robots to allow them to remember and maintain the position of moving parts. Scientists also constructed RAM chips using microfluidic valves rather than electronic transistors. Microfluidic valves were originally designed to control the flow of liquids and control the flow of air. Valves in the system are sealed against a pressure differential even when disconnected from the air supply line creating trapped pressure differentials that function as memories maintaining the state of the robot's actuation.

The team modified microfluidic valves to handle larger airflow rates producing an eight-bit pneumatic RAM chip that controls larger and faster-soft robots. The system is incorporated into a pair of 3D printed rubber hands. The system featured soft robotic fingers that extended when connected to atmospheric pressure and contracted when connected to a vacuum. The team was able to get their soft robotic hand to play a song on the piano.