Columbia Engineering Researchers Make Soft Robotics Breakthrough With New Artificial Muscle

Researchers at Columbia Engineering have made a breakthrough in soft robotics that is said to have solved a long standing issue in creating untethered soft robots. The goal of these soft robots is to mimic the action and movements of natural biological systems. The research team was led by Hod Lipson, a professor of mechanical engineering. The team developed a 3D printable synthetic soft muscle.

This is an artificial active tissue that doesn't need an external compressor or high voltages as other artificial muscles created in the past have needed. One of the key characteristics of this breakthrough is that the new material features a strain density that is 15 times higher than natural muscle.

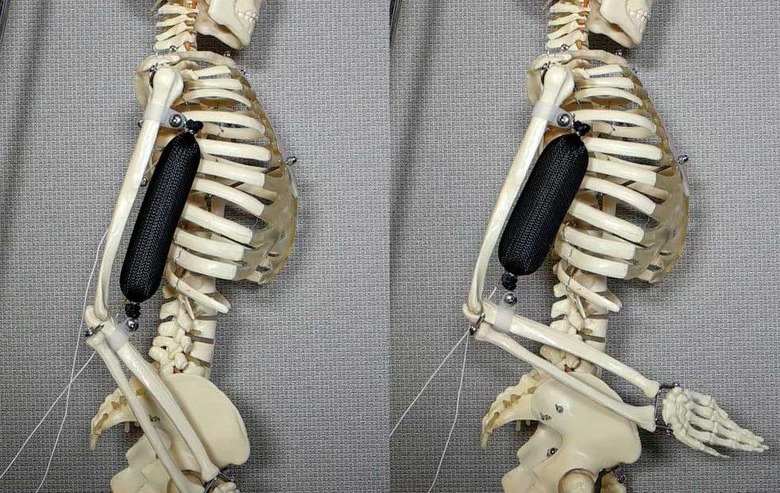

Researchers say that the muscle is able to lift 1000 times its own weight. The previous artificial muscles were limited to being tethered because of the need for external compressors to push air into the muscle or electricity. This has limited the ability to create robots that are able to work and function independently.

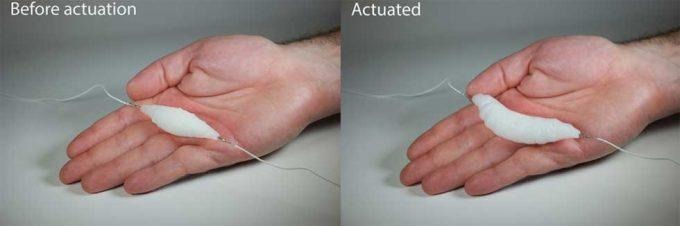

The scientists use a silicone rubber matrix with ethanol distributed through the material in the form of micro-bubbles. The resulting artificial muscle is easy to fabricate, cheap, and uses environmentally safe materials. The material is 3D printed into the desired shape and actuated using a thin resistive wire with low power 8V requirements.

The material is able to expand up to 900% when heated to 80C. The team is now working on a long term plan to replace the embedded wire by incorporating conductive materials. This will increase the response time and shelf life for the muscle. The team also wants to develop an AI able to control the muscle.

SOURCE: Columbia