Carbon3D Creates New 'Terminator' 3D Printing Technique

Until now, 3D printed objects have been created by printing a series of 2D lines on top of each other. The newest technique by Carbon3D is completely different; it creates an object from a pool of resin in one solid sweep using a new Continuous Liquid Interface Production (CLIP) technology. Instead of being slowly built layer by layer, Carbon3D's objects appear to instantaneously take form from a pool of liquid, just like that scene in Terminator 2 where the T2 rises from a pool of molten metal.

If you haven't heard of Carbon3D until now, you're not alone. The company was founded by chemistry professor Joseph DeSimone. His company came out of woodwork with a TED talk on Monday night, coinciding with their scientific publication. DeSimone wants to revolutionize 3D printing for everyone, ranging from individual users to industrial scale applications.

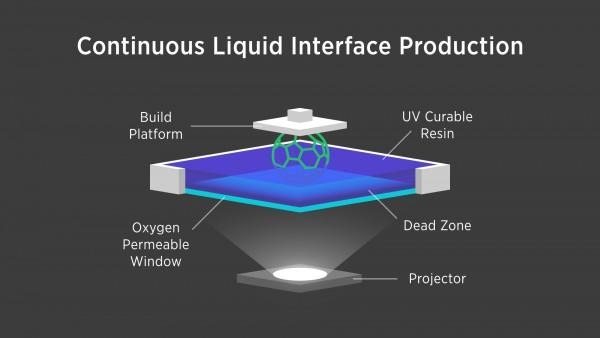

CLIP blasts the pool of resin with programmed pattern of rays of light to harden the polymer resin and uses oxygen to keep it in a malleable liquid state. By programming this set of dual controls, one can create smooth shapes and delicate lattices. Creating negative space has been a hurdle for some traditional 3D printers. Carbon3D's CLIP process can be used to make very fine tubes and lattices, which bodes well for future biomedical applications.

This new, all-in-one 3D printing process is not exactly instantaneous, but Carbon3D has managed to speed it up quite a bit. They claim that their method is 25 to 100 times faster than traditional 3D printing. Carbon3D's CLIP production process creates contiguous figures that are without the disadvantages of unwanted seams or structural weakness along the printed seams that can result from traditional 3D printing's layer by layer technique.

Watch Carbon3D in action.